I’ve long said that this pandemic will push production in-house, and that’s precisely what the Snapmaker 2.0 hopes to do. In its second, more expansive, open, and fine-tuned iteration, the folks at Snapmaker have put together an absolute prototyping powerhouse that fits within a 350x320x330mm framework, and on a budget that’s about as much as your work laptop. The modular device can be built to run as a 3D Printer, a Laser Engraver/Cutter, and even a 3 or even 4 Axis CNC Machine. The Snapmaker 2.0 doesn’t just combine printing, engraving, machining into a single device, it scales it down to a budget-friendly consumer appliance that’s easy to use, and brings powerful fabrication tools right into your home, letting you prototype your own designs right at home, without dealing with external vendors, partnering with FabLabs, or stepping out to prototype your designs at the nearest workshop… all within a budget of roughly $1500.

The Snapmaker 2.0 builds on its predecessor’s ability to let you change modules and turn your 3D printer into a laser-engraver, a CNC carver, or even a 4-axis CNC lathe machine. In its second generation, however, the Snapmaker 2.0 boasts of a customizable assembly that lets you build exactly the fabricating tool you need, allowing you to expand or scale it down based on the size of your operation or your workspace, add a protective enclosure, or even addons like an IP Camera or an emergency kill-switch.

All of Snapmaker 2.0’s components come precisely machined from an anodized aluminum alloy, giving you a device that’s as robust as it is accurate. The machined components boast of incredibly low tolerances, resulting in precise outputs, and the Snapmaker 2.0’s own firmware like its automatic bed leveling system, or the software, the Snapmaker Luban, which lets you preview laser-patterns and artwork before you etch them, just gives you the extra bit of control you need to create the kind of designs you’ve got in your mind. The Snapmaker 2.0’s modules are ridiculously easy to assemble and disassemble, and its flexible design lets you build a machine that’s perfectly sized for your workspace, be it your bedroom, or your garage workshop. Moreover, the Snapmaker’s native software Luban guides you through the whole (incredibly simple) process. It provides a host of features that make it easy for novices (with relatively no skill or understanding of software) to operate it. The touchscreen interface on the Snapmaker 2.0 can alert you when the filament runs out during 3D printing (and even pause the build till you change it), while with CNC carving, Snapmaker 2.0 allows any consumer to easily switch between drill bits (a task that earlier required a CNC expert), and a camera beside the laser aperture even lets you accurately visualize your artwork on your product before you begin fabricating… so what you see, is what you get. An auto-resume feature works exceptionally well if you’re in an area susceptible to power-outages. The device automatically pauses its processes when the power gets cut, allowing you to resume exactly where you left off when the power is restored, ensuring your final output isn’t affected in the process.

The device’s multifaceted approach to prototyping allows you to work not just with a variety of machining techniques but also with a wide range of materials. You can 3D print in a variety of plastic filaments, or CNC-machine materials like acrylic and wood, while laser-engraving on multiple mediums from paper to fabrics, leather, wood, plastic, and even composite materials. Designed for embracing creativity, the Snapmaker 2.0’s modules are easy to replace, and the machine automatically identifies the module you’ve plugged in, adjusting the touchscreen interface to match.

The Snapmaker 2.0 is running a special discount for YD readers, with an extra $50 off on their current Black Friday deal. Go ahead! You can literally build your own production line in your home… or better still, design your own holiday gifts!

Designer: Snapmaker

Click Here to Buy Now: $1,559 $1,799 ($240 off). Hurry, YD readers get an extra $50 off (use code: 20HSYD). Offer ends in 48 hours!

Snapmaker 2.0 Modular 3-in-1 3D Printers

The Snapmaker 2.0 is a modular 3-in-1 3D printers that unlock your full creative potential, from 3D printing to laser engraving, cutting, and CNC carving. Snapmaker 2.0 is smarter, faster, larger, and more powerful than ever before.

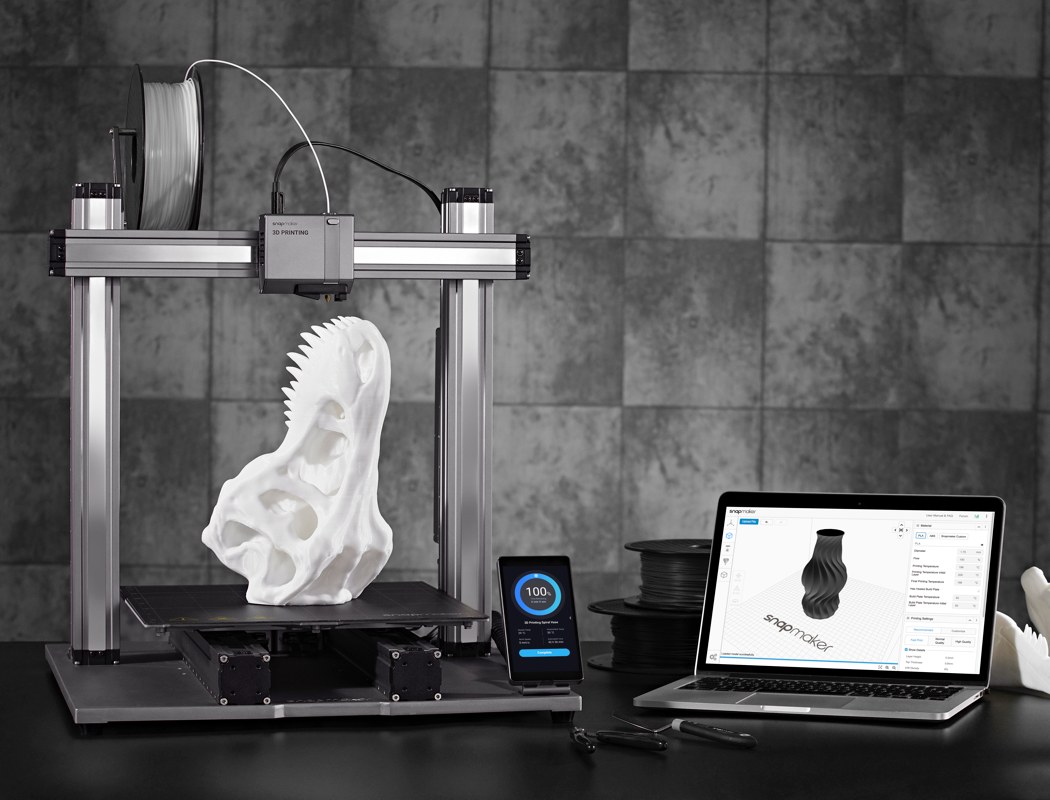

3D Printing

Snapmaker 2.0 modular 3-in-1 3D printers are ideal for beginners who are just getting started, hobbyists who prefer more customized options, as well as engineers and designers who want to print large objects or accurate parts with outstanding print quality.

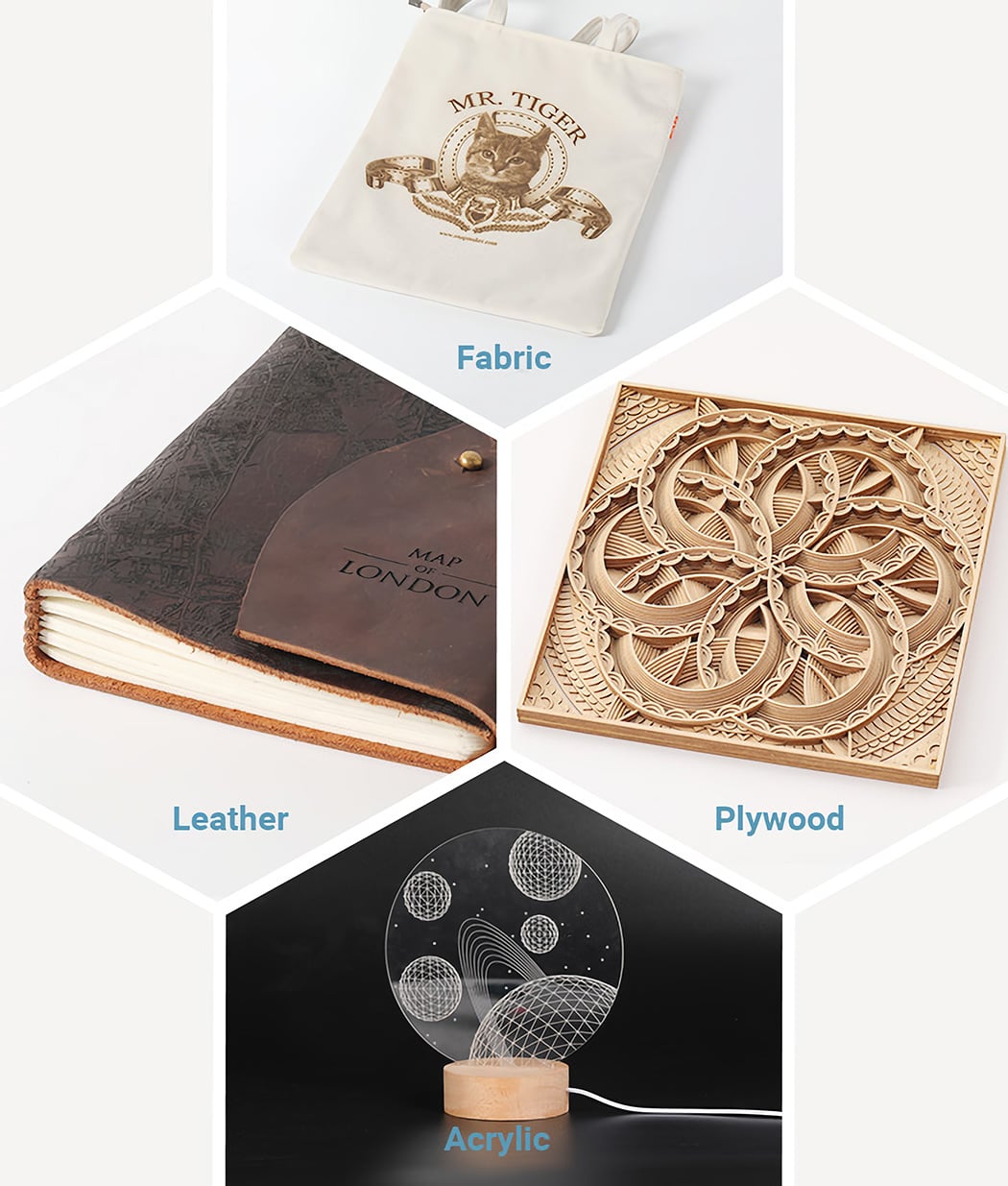

Laser Engraving & Cutting

Traditional 3D printers can only 3D print. Your Snapmaker 2.0 is completely different. With interchangeable modules, Snapmaker’s functionality can be changed quickly and effciently, just like changing lenses on a camera. Now you can make many kinds of beautiful and artistic creations using laser engraving and cutting.

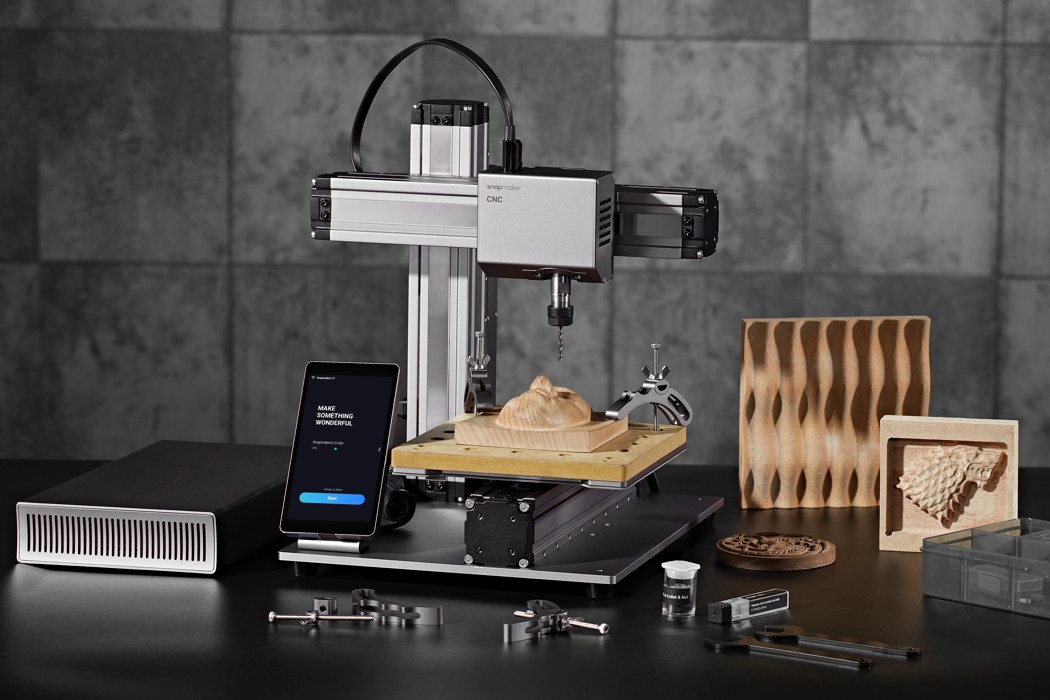

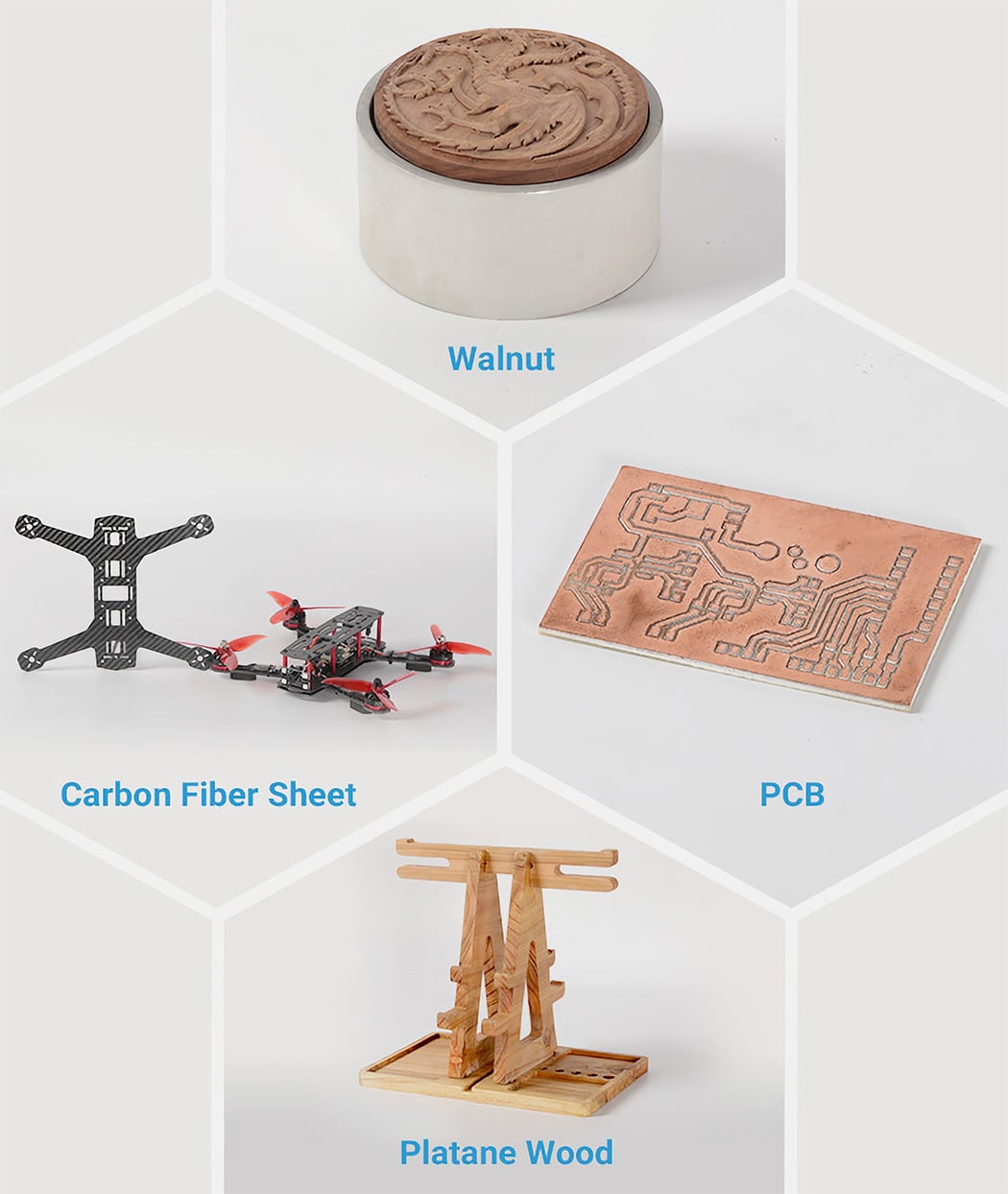

CNC Carving

You can even use Snapmaker 2.0 as a CNC router to create precision 2.5D and 3D objects. It has faster working speed and a much larger workspace than the original model. It is the perfect machine to extend your interest to CNC carving.

3D Printing Samples

Snapmaker 2.0 allows you to print almost anything for your creative projects: from common applications to objects with specific mechanical properties, such as toughness, durability, and flexibility. Snapmaker 2.0 can do it all!

Laser Engraving & Cutting Samples

A wide variety of materials you find in daily life are laser engravable or cuttable, including paper, plywood, leather, acrylic, cardboard, paper, fabric, and even food like cookies and coconuts!

CNC Carving Samples

CNC carving is ideal for precisely carving or cutting hard materials. With Snapmaker 2.0, you won’t be limited with the options of plastic or soft materials, and you’ll be able to use the following materials for your creative projects: hardwood, PCB, acrylic, POM, carbon fiber sheet, and many more materials.

High Resolution

Built with high-precision parts and an overall upgraded design, Snapmaker 2.0 is able to consistently print, engrave, cut, and carve objects in high resolution. The repeatability of the machine is 0.005 mm, and the homing repeatability is 0.01mm.

Modular 3D Printer

Imagine a 3D printer that you can upgrade and customize. Snapmaker is more than just a series of machines. It’s a system of powerful modules and add-ons for creative people like you. You can enjoy a lot of new features simply by getting the new modules or new kits.

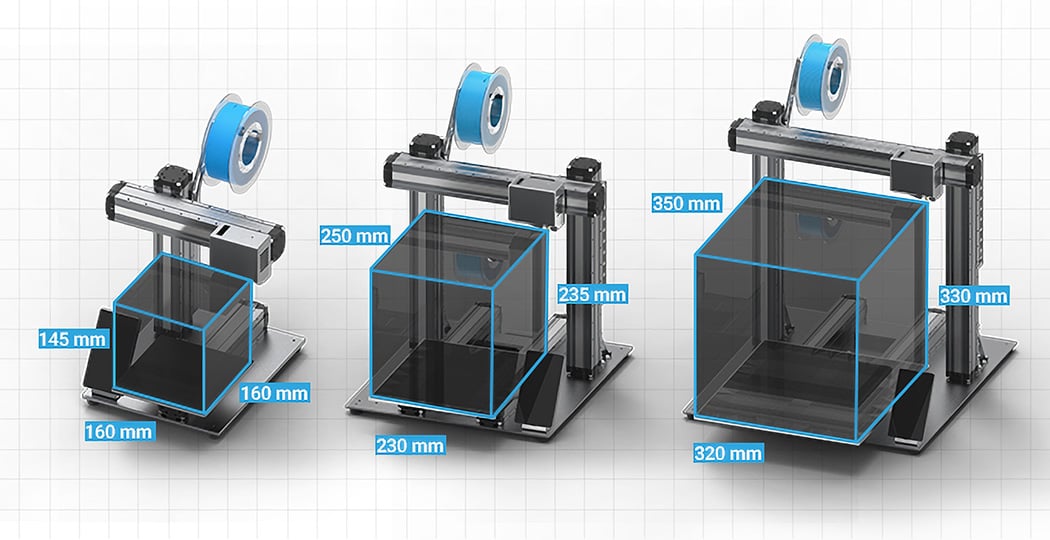

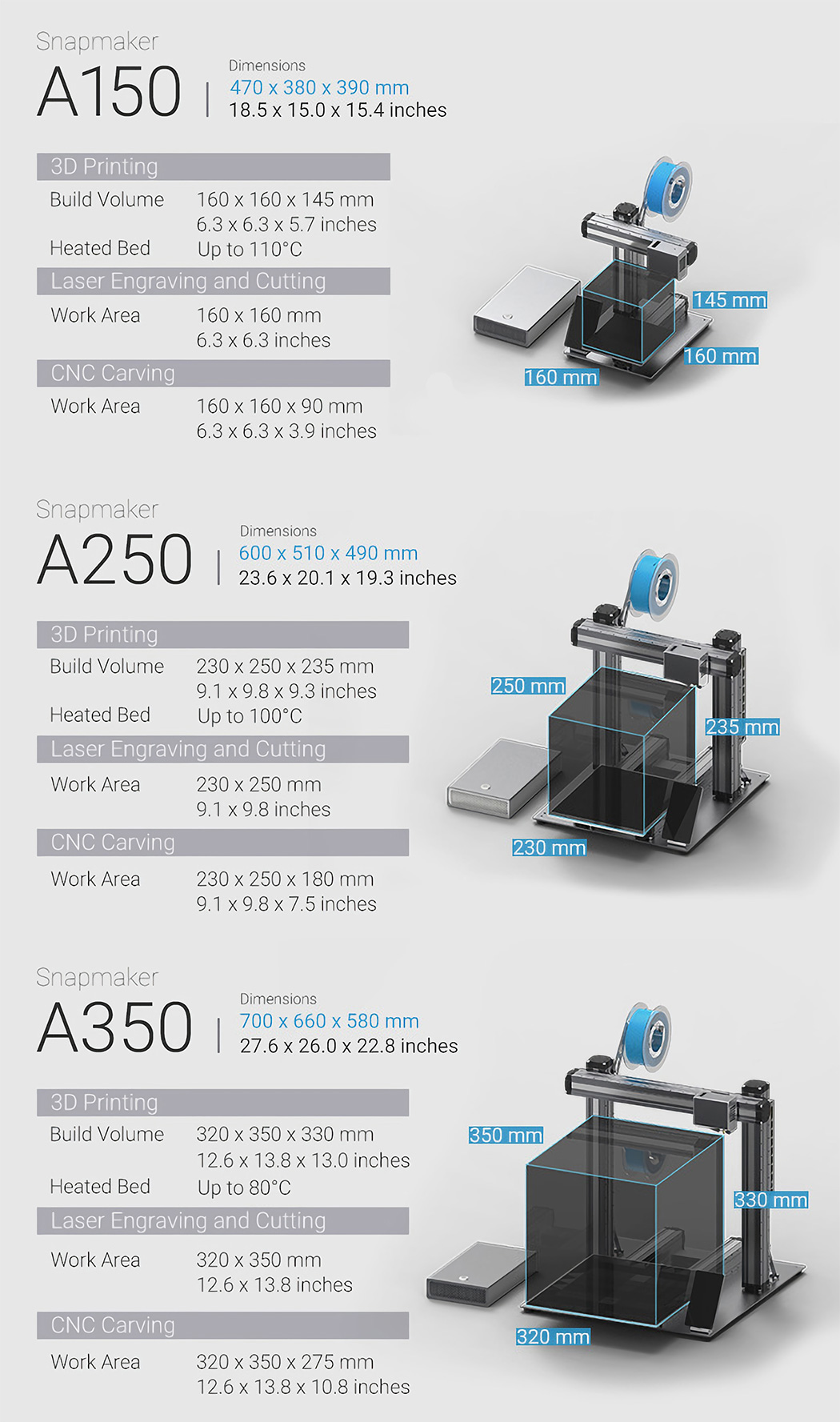

In 3 Sizes

Snapmaker 2.0 has three models: A150, A250 and A350. You can make large prototypes, or multiple smaller objects in one go. A350 provides the largest build volume, measuring 320 x 350 x 330 mm.

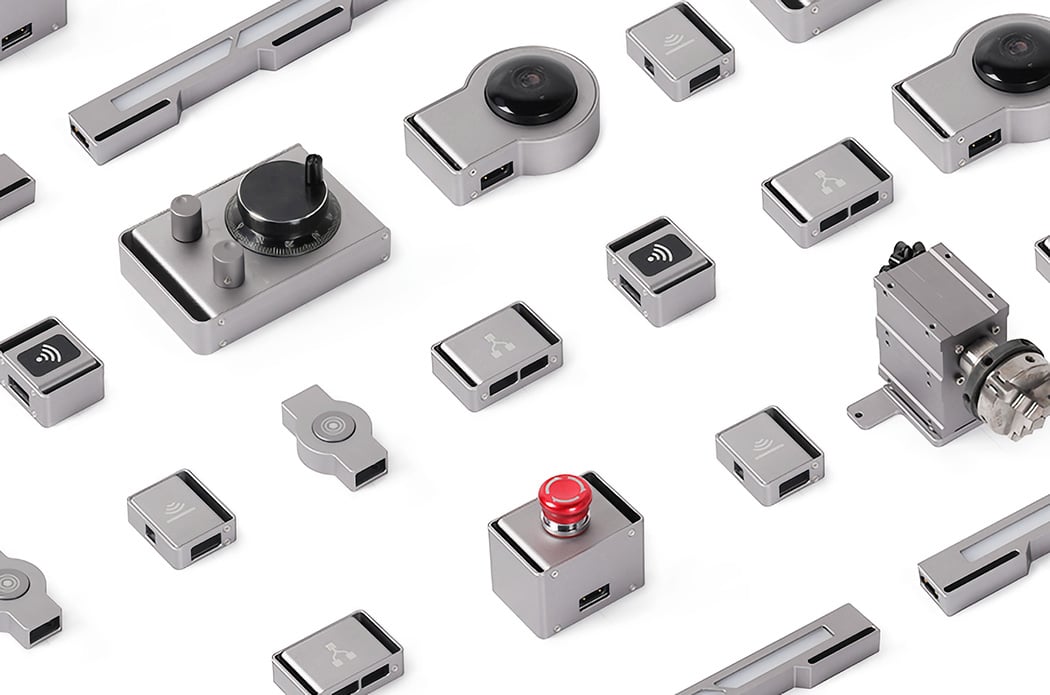

Add Ons

As an innovative Snapmaker owner, you can further enhance your creativity with a wide variety of add-ons to personalize your Snapmaker 2.0. For greater level of applications, we’ll have Enclosures, Lights, a Handwheel, an Emergency Stop Button and a Camera available for preorder soon!

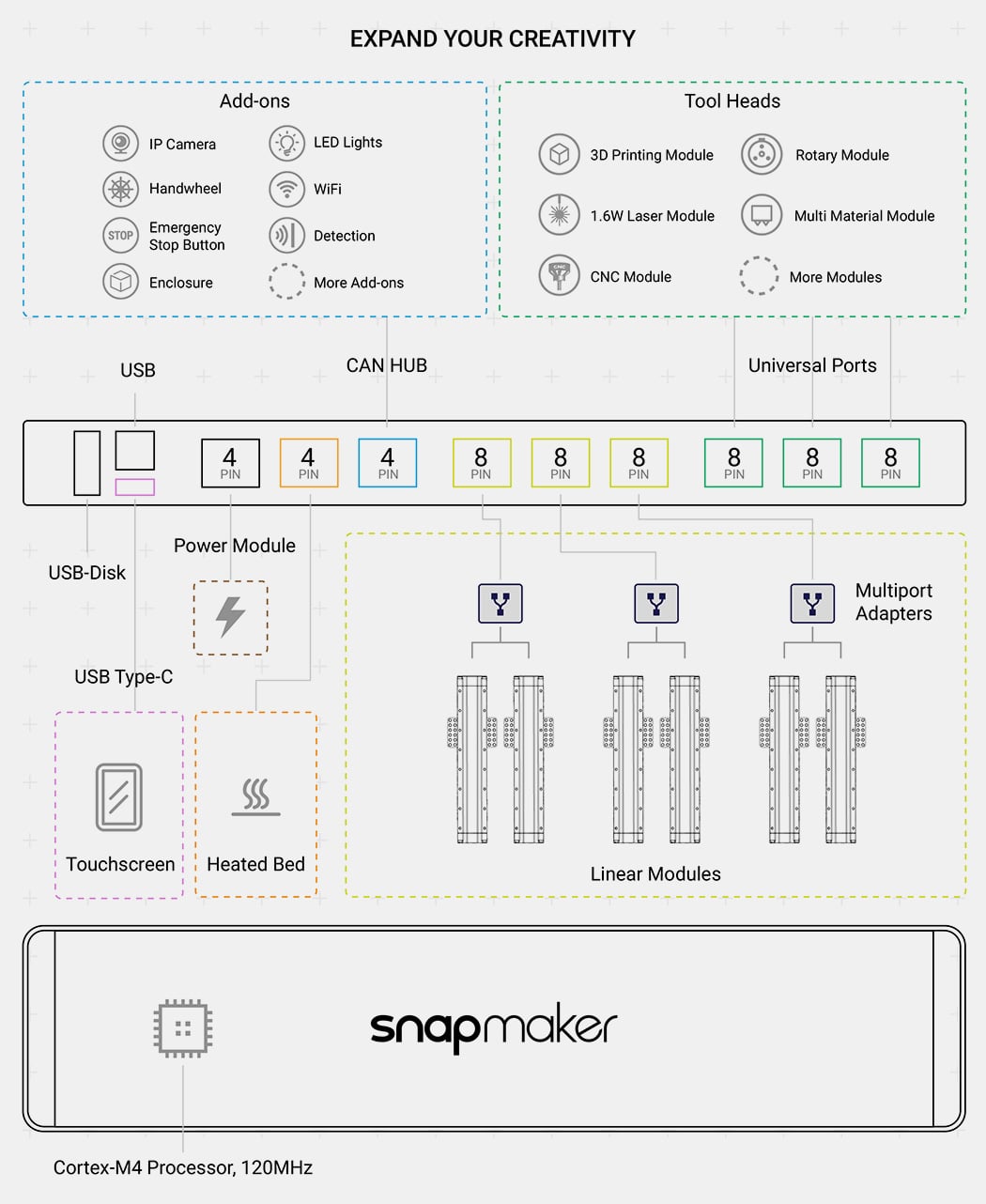

Powerful Controller

Snapmaker 2.0 can support various tool heads, add-ons, multiple linear modules, and more features using simply one controller. A big reason we are able to do this is that we innovatively adopt the CAN (Controlled Area Network) bus expansion solution which was widely used in car automation. Rather than adding more ports and make a bigger control board with tangled cables, we’ve upgraded our controller to expand your creativity by providing universal ports, multiport adapters, and a CAN Hub for adding additional CAN-bus ports.

Future Expansion

The Snapmaker 2.0 is modular. It allows for one machine to fulfil many roles which reduces space and cost. Snapmaker A150, A250 and A350 can be transformed into even more powerful machines with the upcoming Snapmaker Rotary Module, High Power Laser Module, 700W Spindle Module, and longer linear modules!

All-metal

All the Snapmaker models are built to last. For Snapmaker 2.0, we pushed the boundaries of all-metal construction even further. All modules and major components are made of high strength metal. For example, both the controller board and power adapter use aluminum alloys housings for better heat dissipation; the original POM rollers are upgraded to steel rollers to deliver a higher load-bearing capacity and rigidity.

Well-made

The aerospace-grade aluminum alloys are made into precision, reliable parts of Snapmaker modules after a series of processing steps. Each manufacturing process is strictly controlled, and every part is meticulously made. Snapmaker 2.0 not only looks premium, but also consistently delivers high performance.

High-precision

Snapmaker 2.0 allows the high-precision computer-controlled tools to be readily accessible for every desk. Integrating only the finest quality components, it has high accuracy and repeatability, which allows it to 3D print, engrave and cut objects in high resolution.

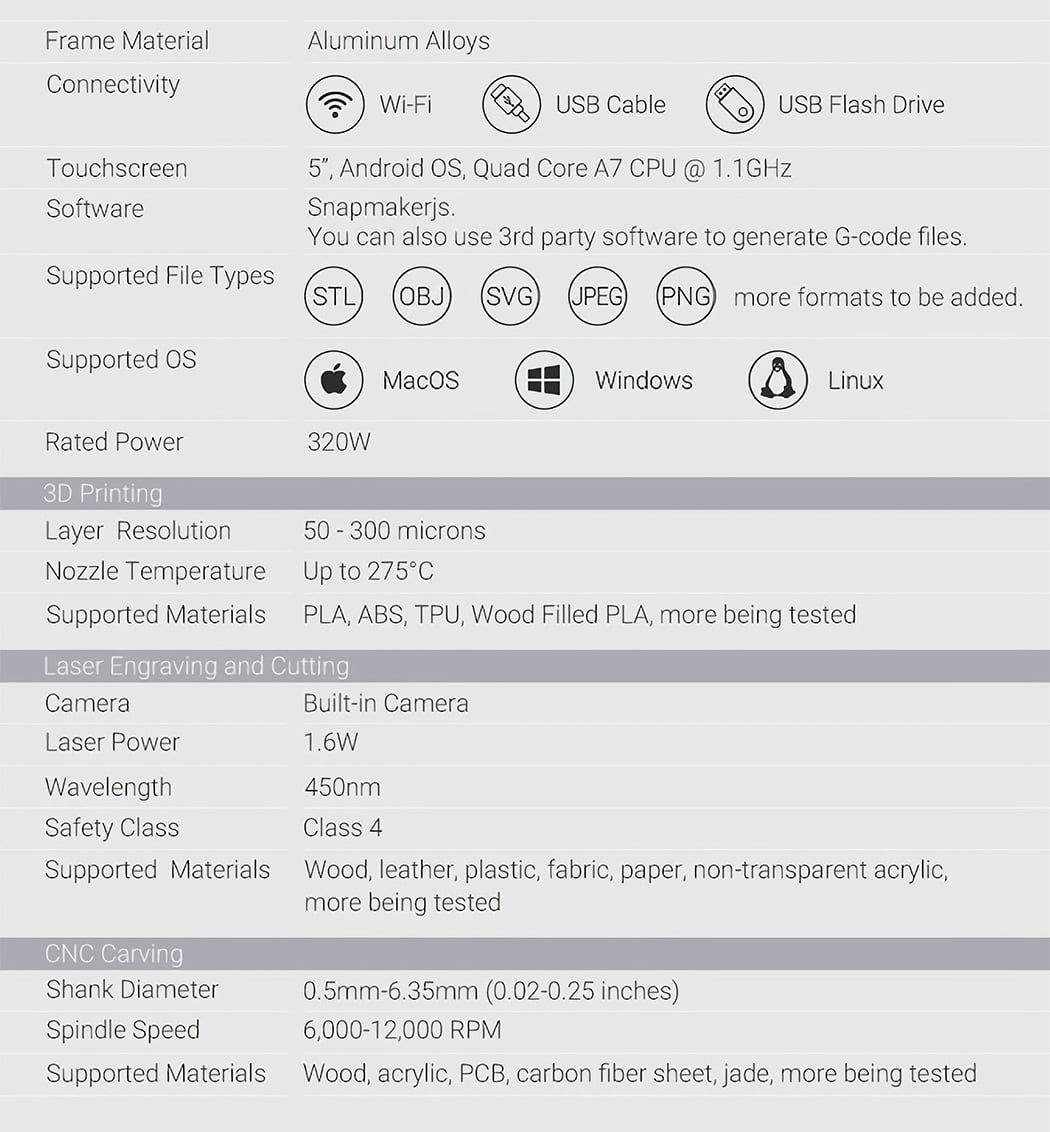

Easy-to-use 3-in-1 Software

Our 3-in-1 software, Snapmakerjs, is tailor-made for your Snapmaker machines. One single and powerful software for all your tasks.

WiFi Connectivity

With the Wi-Fi feature and the USB port, you can connect your Snapmaker 2.0 to any configuration for your convenience. You can upload designs via Wi-Fi or USB flash drive and print with the touch of a button. In addition, you can update the firmware over Wi-Fi directly.

Smart Touchscreen

Snapmaker 2.0 comes with a smart touchscreen that simplifies the workflow of your daily projects, letting you manage the most-used tasks directly from the touchscreen. Similarly to a smartphone, this 5-inch (720 x 1280 pixels) movable touchscreen is equipped with a Quad Core A7 CPU @1.1GHz, running under Android OS. providing a smooth and fast interface.

Power-loss Recovery

You don’t have to worry about power outages anymore. Snapmaker 2.0 can automatically detect power-loss, and then resumes exactly where it left off. You can recover any project and get perfect printing/engraving/cutting/carving results all the time.

Easy to Assemble

3D Printing Highlights – Auto Leveling

Bed leveling is a tricky process, especially for a large heated bed and inexperienced users. To make bed leveling easier, we added an auto-leveling function. An induction sensor can probe the bed in a grid and apply mesh-based compensation that ensures you print on a level bed every time, all without the user having to go through complicated process.

Filament Runout Recovery

Equipped with a filament runout sensor, those who are looking to print a large object can now print without fear. This will prevent unfinished prints and “air printing”. Once it realizes that the filament has run out, the touchscreen will notify you to load a new filament and allow you to resume printing immediately.

Upgraded Cooling System

With Snapmaker 2.0, you can print objects with deep overhangs and get a more smooth finished surface! Cooling is just as important as heating when it comes to FDM 3D printing. For the Snapmaker 2.0, the cooling system is re-designed to cool the print in the most efficient way.

Flexible Platform

Removing a print is now easier than ever. Just lift the plate and flex it, no matter the size or shape of your print. As the heated bed uses a magnetic design, you can easily remove and put back the print sheet, or change it with the laser cutting work table or CNC carving in one minute.

Laser Highlights – Built-in Camera

The built-in camera allows you to preview your design with whatever material you use. You can edit your design and precisely position it exactly where you want it to be. What you see is what you get!

Draw, Cut and Capture

Laser cutting can be as easy as drawing. The Snapmaker 2.0 can recognize and transform your drawing into a vector image for laser engraving or cutting. Furthermore, you can edit the converted vector image directly in the Snapmaker software to fit into all your creative projects!

Faster Engraving

Faster is better. We added the Line (Normal Quality) mode to provide you a fast engraving option for grayscale images. This feature can save you hours when engraving big grayscale images. The quality is still very good compared to the original Dot (High Quality) mode.

Aluminum Grid Table

The Aluminum Grid Table is specially designed to prevent damage to the bed by defocusing the laser beam during cutting. It is removable and super firm.

CNC Highlights – ER11 COLLET

Snapmaker 2.0 features a fully upgraded CNC module. Using the standard ER11 Collet, it guarantees a better concentricity that allows for faster CNC carving speed and larger step down, which saves your time significantly. It also supports over one hundred carving and cutting bits. The diameters of the bits range from 0.5mm (0.020 inches) to 6.35mm (0.250 inches).

Wasteboard and Clamping Kits

Each Snapmaker 2.0 comes with an MDF wasteboard. It’s removable and it can protect the bed from damage as well as providing a smooth and leveled surface for precise CNC carving. Furthermore, you can use the provided aluminum clamping kits to hold down the materials more easily and more reliably.

Dust Resistance

Snapmaker 2.0’s linear module has been upgraded for easy maintenance. The leadscrew, driver chip and precision parts are completely enclosed in the aluminum alloys housings. It eliminates the problem of dirt accumulation, resulting in better durability.

Specifications

How Snapmaker 2.0 is made

Click Here to Buy Now: $1,559 $1,799 ($240 off). Hurry, YD readers get an extra $50 off (use code: 20HSYD). Offer ends in 48 hours!