Sneaker culture has encouraged creativity but also added to a lot of waste since it is a part of fast fashion. Traditional sneakers have a short lifespan and with ‘drops’ increasing, people tend to buy and throw much faster. The complicated construction and the use of different materials (rubber, textile, various plastics, etc.) make these almost impossible and unprofitable to disassemble or recycle which is why Burfeind designed Sneature which is a sustainable sneaker alternative for the eco-conscious sneakerheads.

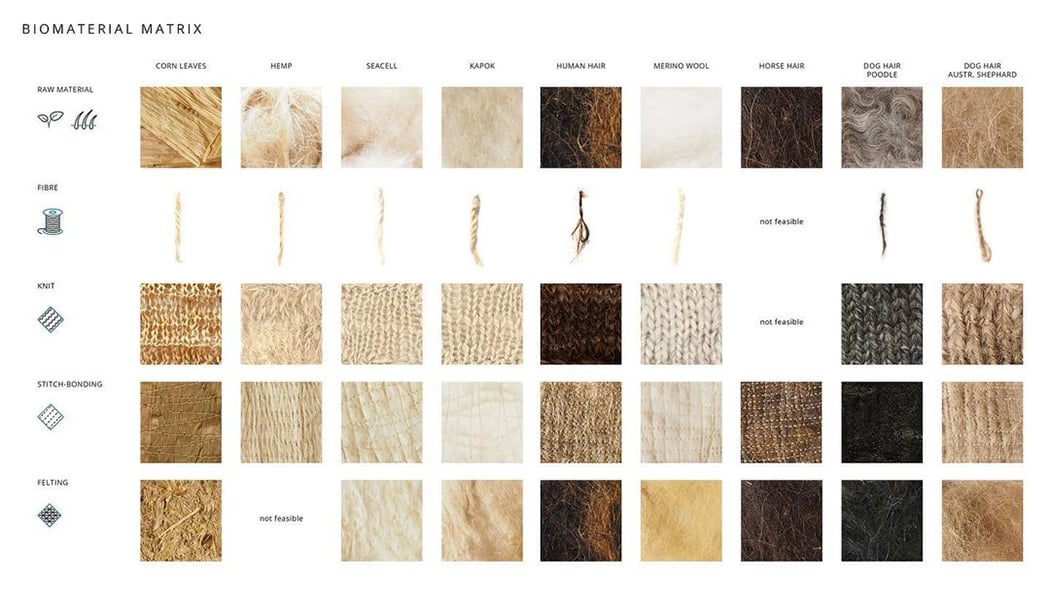

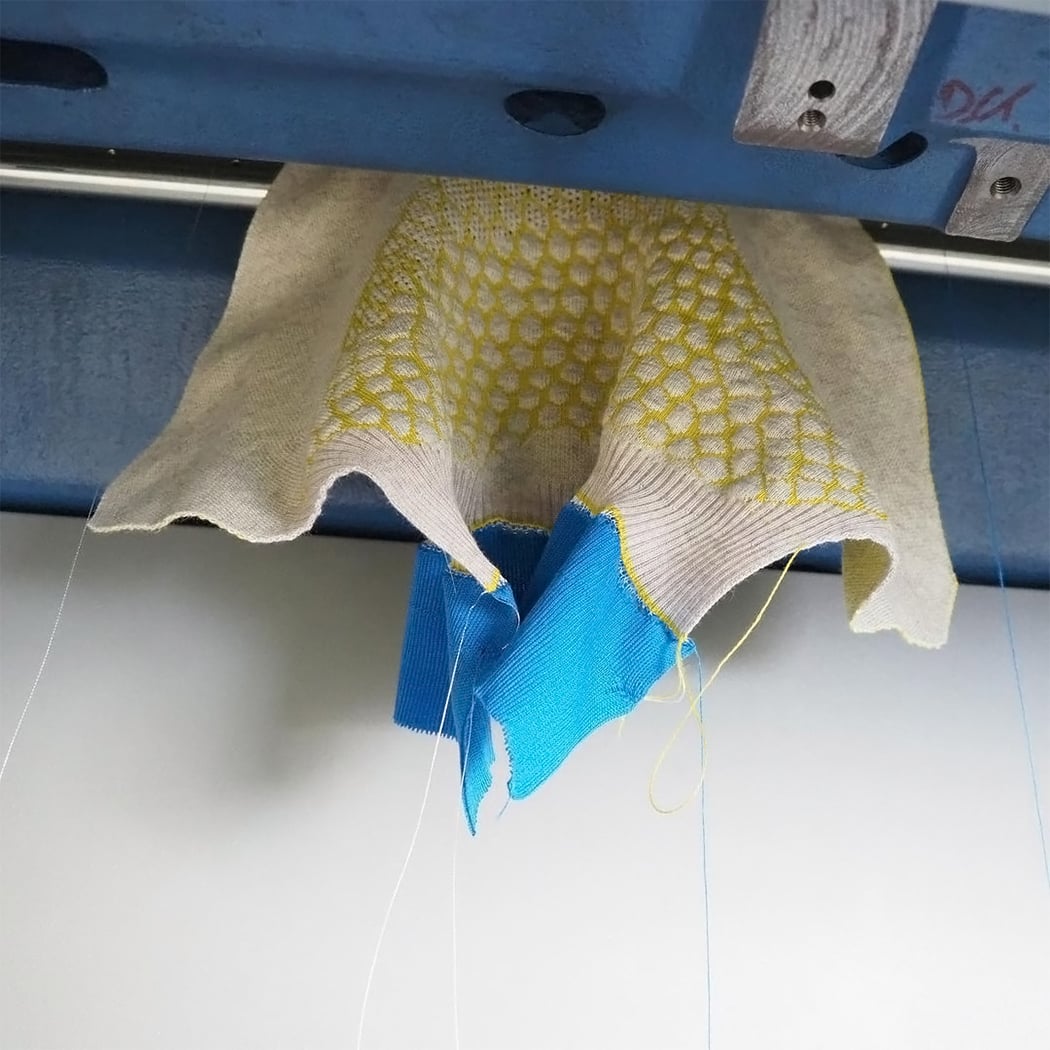

The shoe is crafted from many waste materials. The yarn made of dog hair (Chiengora) which is a biological waste being upcycled – this is innovation. Sneature is biodegradable as well! The design does take into account the functional requirements of a trainer and individual customization by the user. The process uses a 3D knitting technology that allows for customization and on-demand production while using the lowest possible energy consumption method.

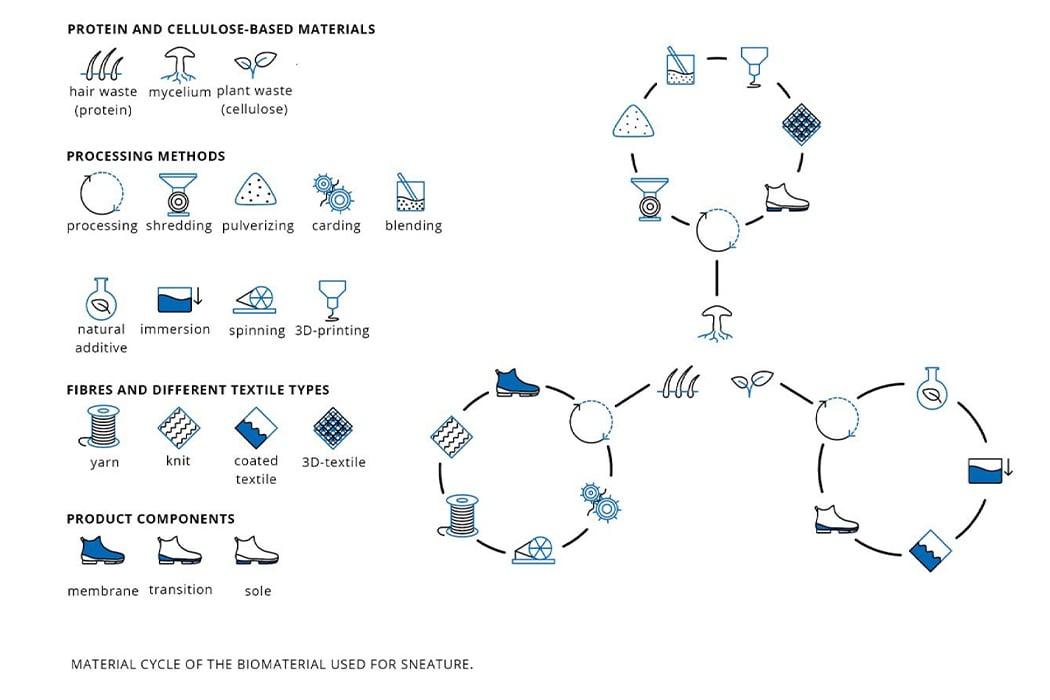

The membrane is a protein-based 3D knit made from dog hair. It transports the functional properties of flexibility, stiffness, and air circulation with a very second-skin feel, similar to the sock sneaker style we’ve been seeing. These materials have natural properties that provide water absorption and release and anti-static properties. A thin layer of flexible bio-rubber/bioplastic forms the transition from the membrane to the sole. The junction of the membrane and sole is water-repellent against splashing or moisture from below awhile protecting the membrane in areas that quickly wear out. The transition also serves as a cushion and protects against rapid abrasion of all other areas in order to extend the lifespan of the shoe. The sole is made of mushroom mycelium which can be used as a composite material with local vegetable waste. The area is designed to be made of bioplastics which means this material can be produced at home or in a maker‘s lab like DIY materials.

“The sneaker was segmented into functional and structural areas (membrane, transition, sole) in order to implement the tested materials in a suitable way, taking into account the functional properties of the different areas. Because of the possible integration into an industrial production process, the membrane – the integrative core of the shoe – was created using a 3D-knitting technique. In order to approach the problem and conceptualize a solution, a fundamental factor for the ecological properties of every product – the material was examined. The design is based on a series of material experiments with natural raw fibers,” says Burfeind.

Designer: Emilie Burfeind