Ensuring that an aircraft maintains a lightweight body and structure is critical for a few reasons. The lighter the aircraft, the less expensive it is to fly. As additional weight is added to any aircraft, more fuel is needed to fly, which in turn means that more CO2 gas emissions are released during flight. Keep that in mind the next time you’re transferring piles of underwear from your suitcase to your carry-on in the middle of the airport lobby. In order to provide the lightest business class seat possible, JPA Design teamed up with Williams Advanced Engineering and SWS Aircraft Certification to create AIRTEK.

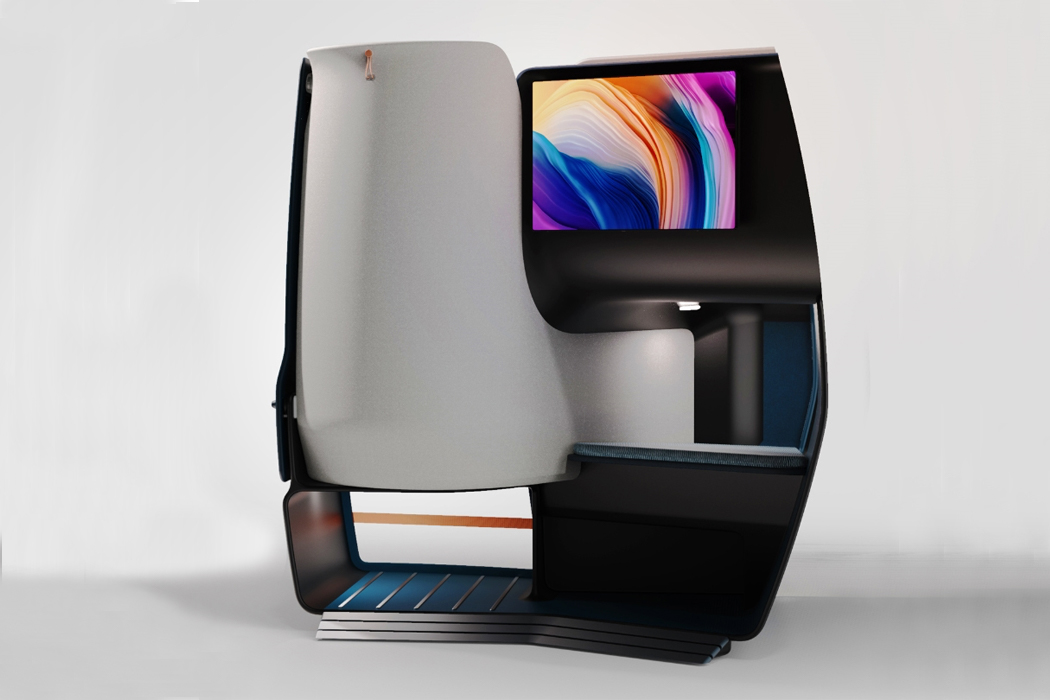

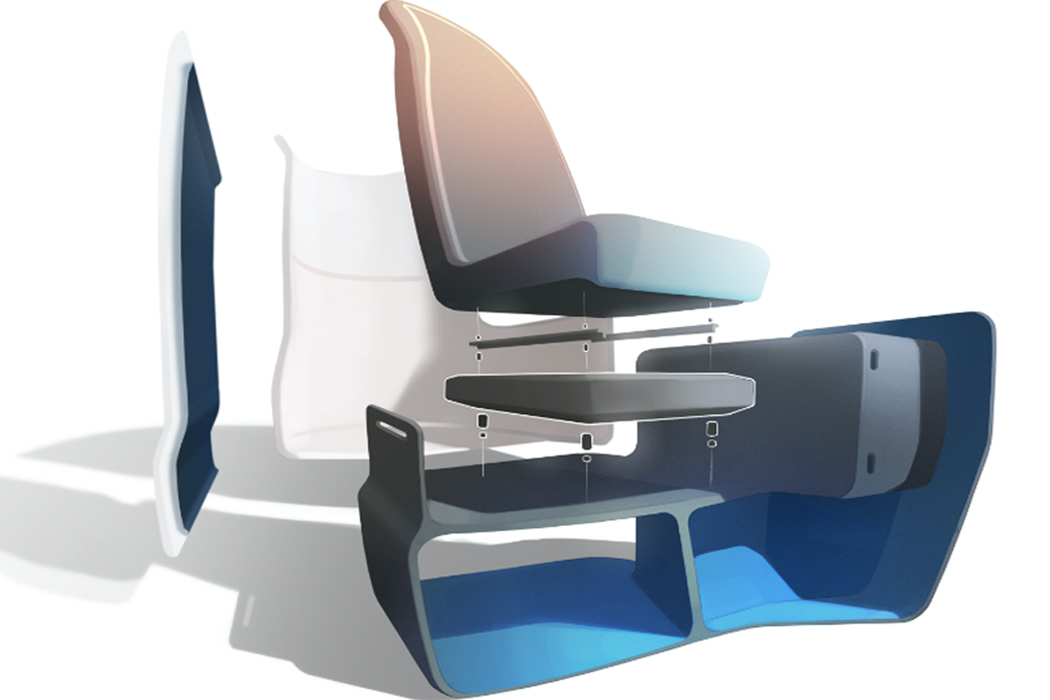

JPA Design’s aim is simple: to produce an all-composite seat structure to help airlines save fuel and CO2. In doing so, the brains and operation behind AIRTEK have produced an ultralight seat that’s durable and thick, constructed from recycled materials to reduce its carbon footprint without compromising comfort or storage. In order to achieve all of this while maintaining AIRTEK’s lightweight quality, JPA Design designed the seat to be self-supporting so that its loads are supported by the skin and shell of the seat.

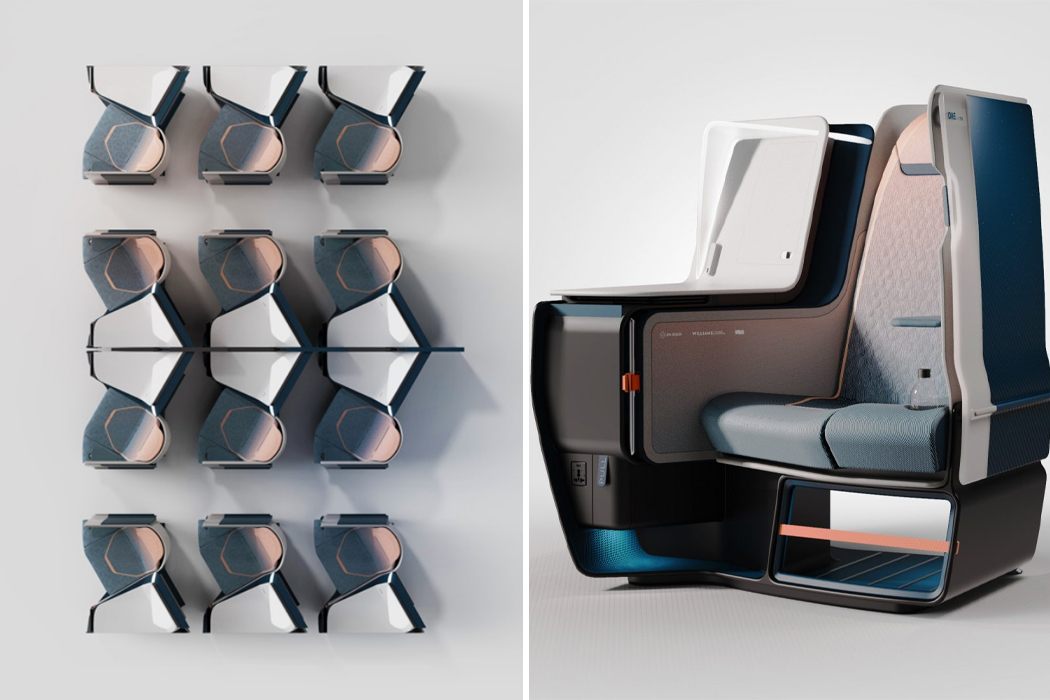

Since the seat is largely self-supported, fewer internal structures are required for construction, lending to a more lightweight, yet plush aircraft seat. In addition to a lighter weight, fewer internal structures result in more room for customer perks like more legroom and extra storage space. AIRTEK’s lightweight form and structure not only provides customers with aircraft benefits for long flights and extra carry-on bags but also allows airlines to carry passengers to and from destinations and burn less fuel in the process.

In designing AIRTEK, JPA Design managed to create a patented unibody, composite, monocoque aircraft structure entirely built from recycled materials. From its conceptualization to its construction, the makers behind AIRTEK remained devoted to their initial aim. Setting out to help save fuel and CO2, JPA Design sculpted an ultralight business class seat, with credit to a skillful combination of technical engineering and artful craftsmanship.

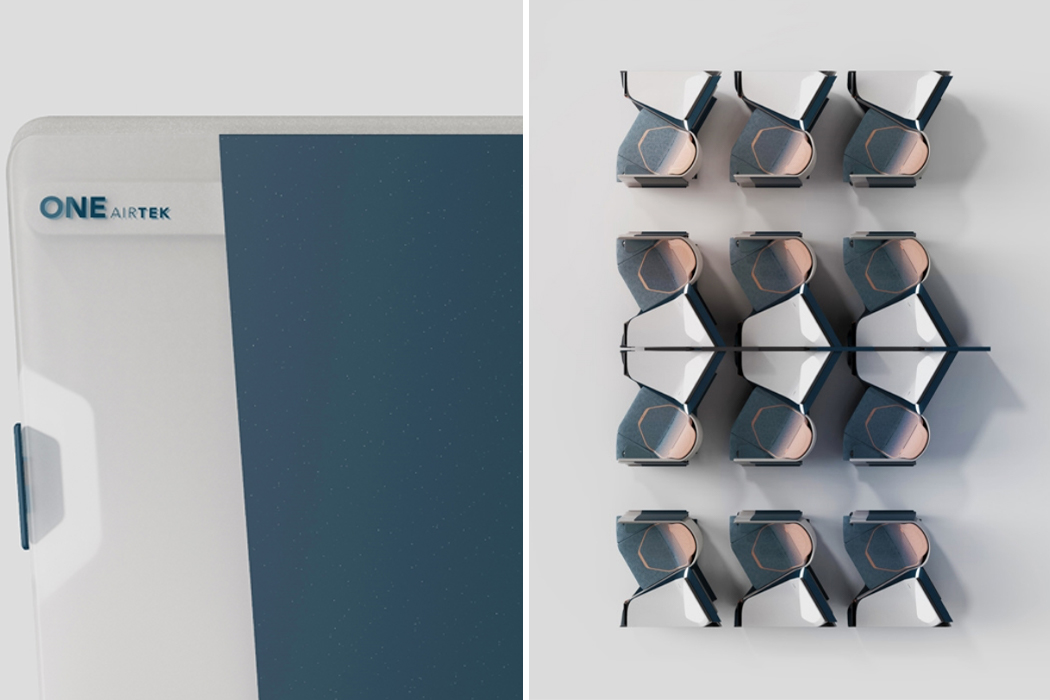

Designers: JPA Design x Williams Advanced Engineering x SWS Aircraft Certification

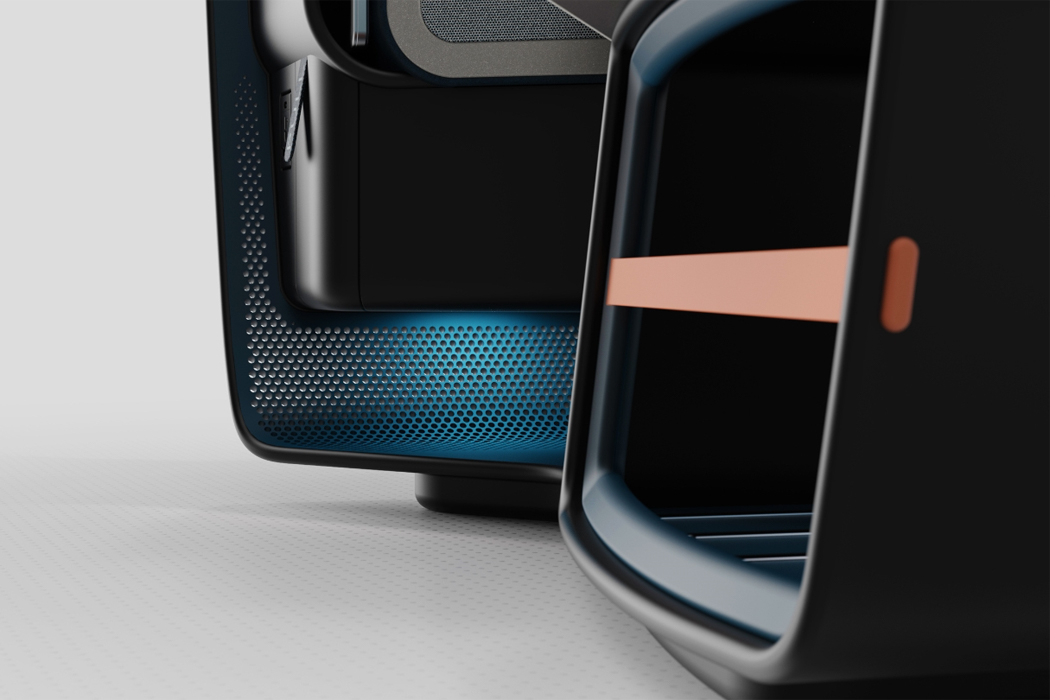

AIRTEK’s monocoque build and self-supported seat provide extra storage area and legroom.

Without the need for extra internal structure, AIRTEK allows more space for customer benefits.

“Our aim is to produce an all-composite seat structure, for optimization of seat mass, which in turn will lead to airlines saving fuel and CO2.”

“The ultra-light seat is designed with durable, single material thicknesses and surrounded by safe storage places for your laptop, cabin bag, and personal items.”

The extra storage bin provides travelers with supplemental security when stowing sway their bags, thanks to an elastic strap.

The extra storage bin provides travelers with supplemental security when stowing sway their bags, thanks to an elastic strap.

The coat hook from AIRTEK was inspired by fashion footwear, providing a strong, minimal hook.