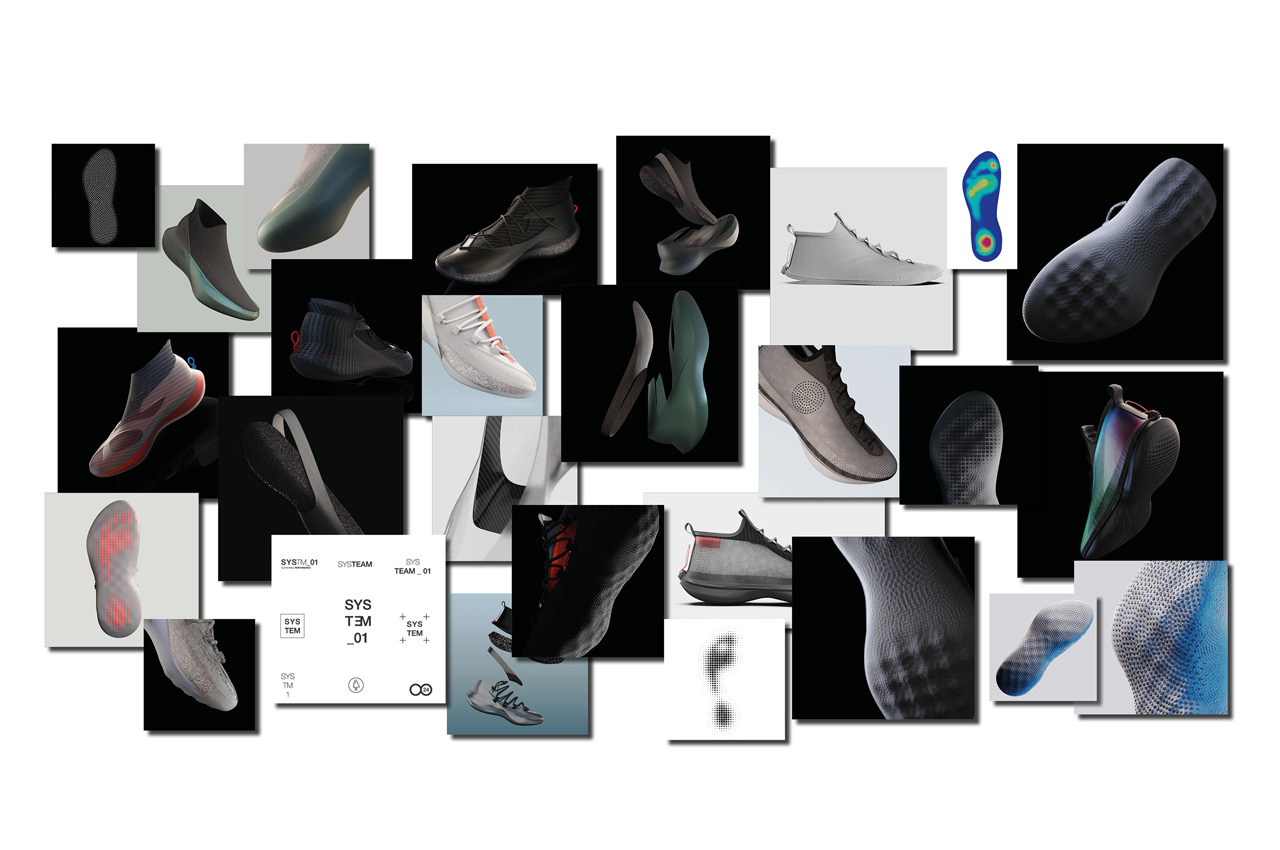

Basketball shoes need a perfect blend of breathability, cushion, support and traction. Owing to the performance load, they tend to wear out quickly only to end up in landfills. As an ingenious alternative with the same prowess, an industrial designer with a love for basketball and shoes has conceived a 3D printed modular sneaker system that is built to match the standards of a Dunk High yet thrives on its concept of reparability.

The idea of sustainability is penetrating the footwear industry in a major way to say. While startups and indigenous manufacturers have made the first long stride, it’s the market leaders like Nike and adidas that are now catching up with their performance footwear donning a green conscience. Basketball shoes have not yet been touched by this wind of change; evidently, that’s really not how it will be in the years to come and already a unique concept proves that obvious.

This sustainable basketball sneaker is conceptualized by Dennis Johann Mueller. It has been through a lot of back and forthright from the drawing table to the prototype but the final outcome in images is by and large a concept that deserves to see the light of day with subtle commercial tweaks of course.

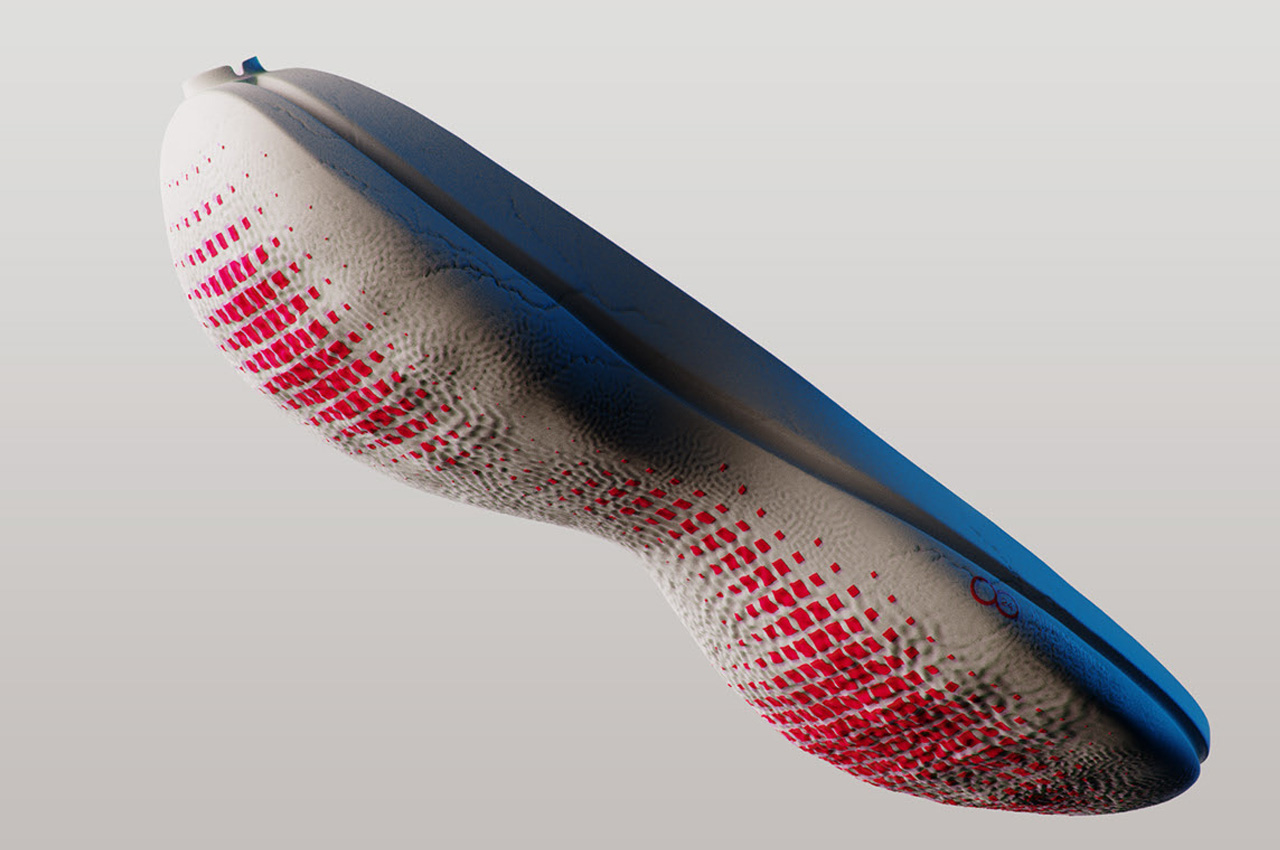

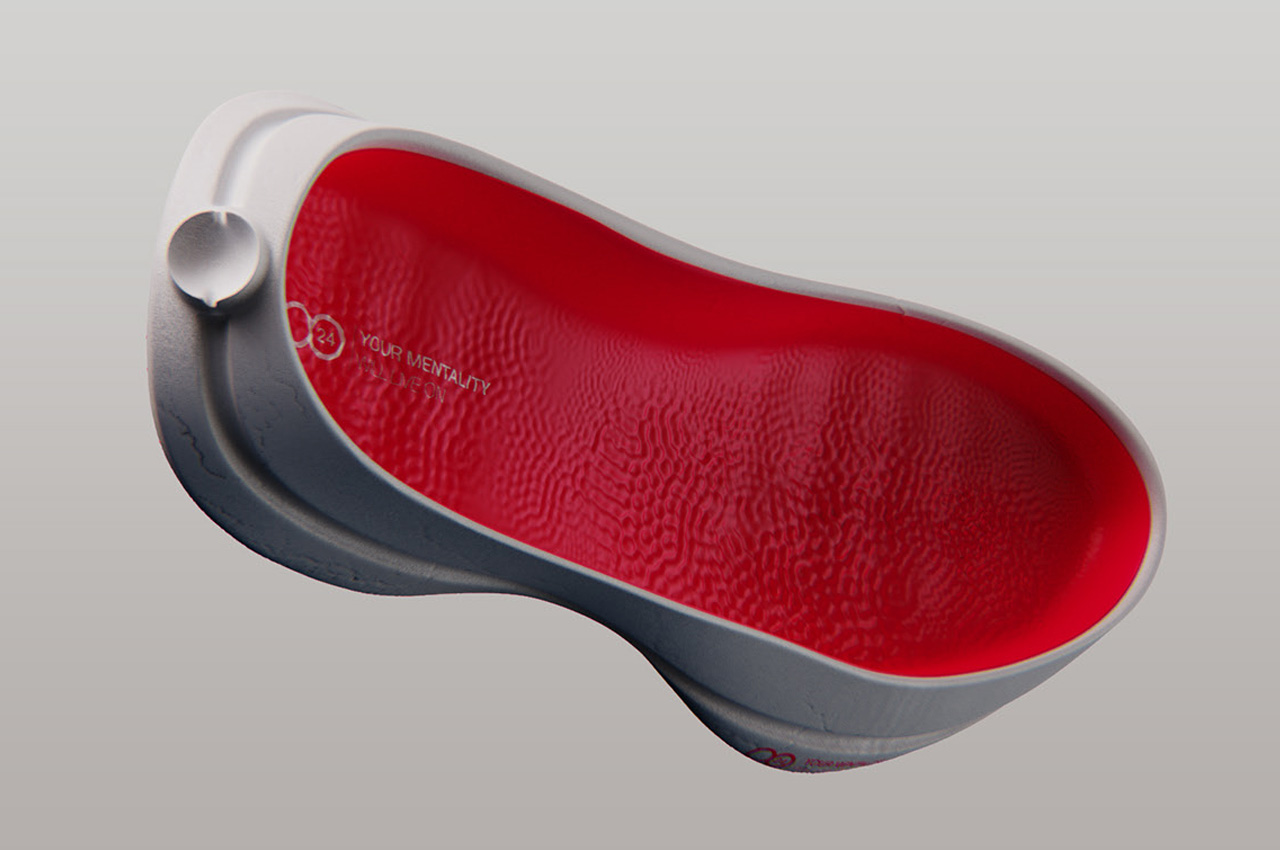

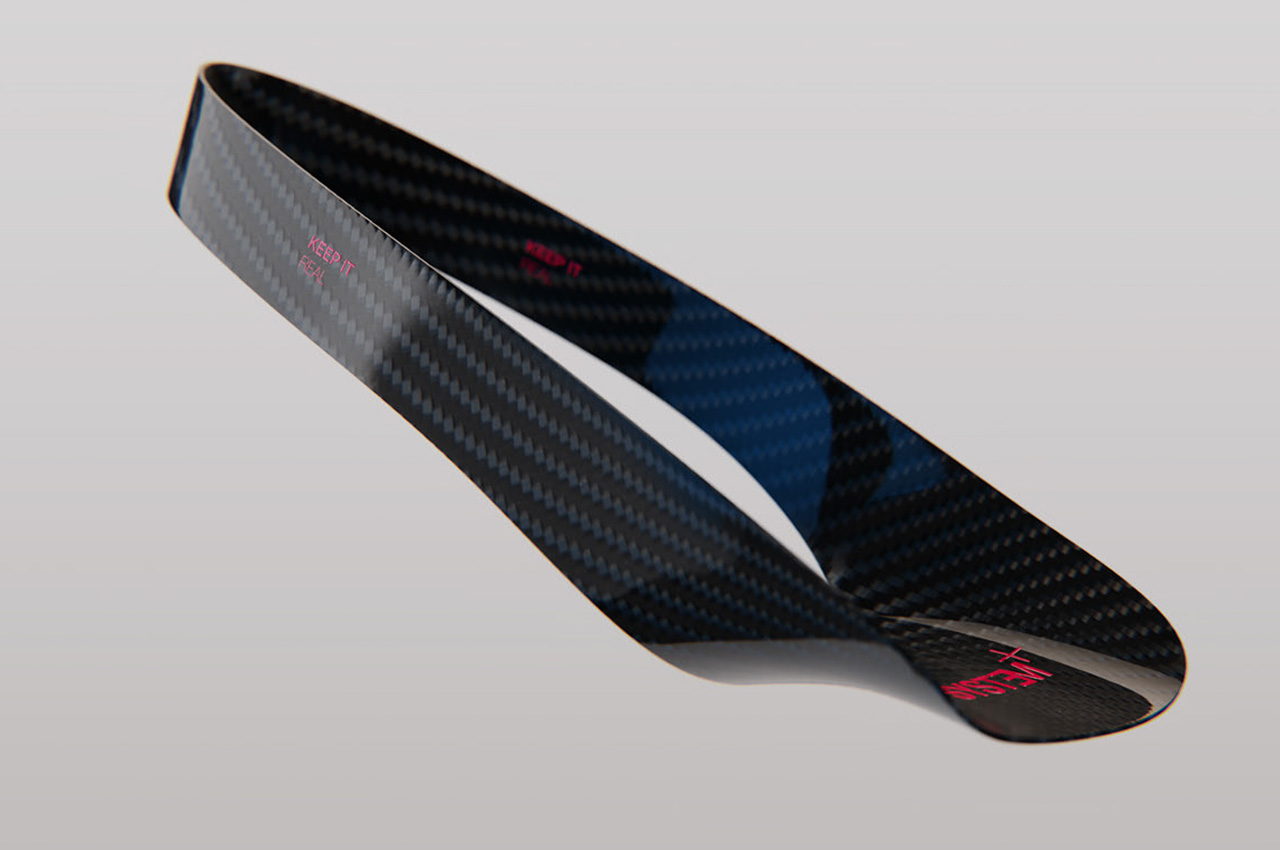

The silhouette for me is primarily a rage for its reparability quotient, much like the good conscience Fairphone. The shoe is designed in detachable parts; for instance, the upper, shankplate, midsole and outsole are all separately created to finally form a cohesive unit that can be worn to the hardwood court. This design basically offers users the freedom to adjust different shoe parts to their varying comfort and playing needs, and when they begin to wear out, only have the affected part recreated and replaced so the shoe can be worn as new.

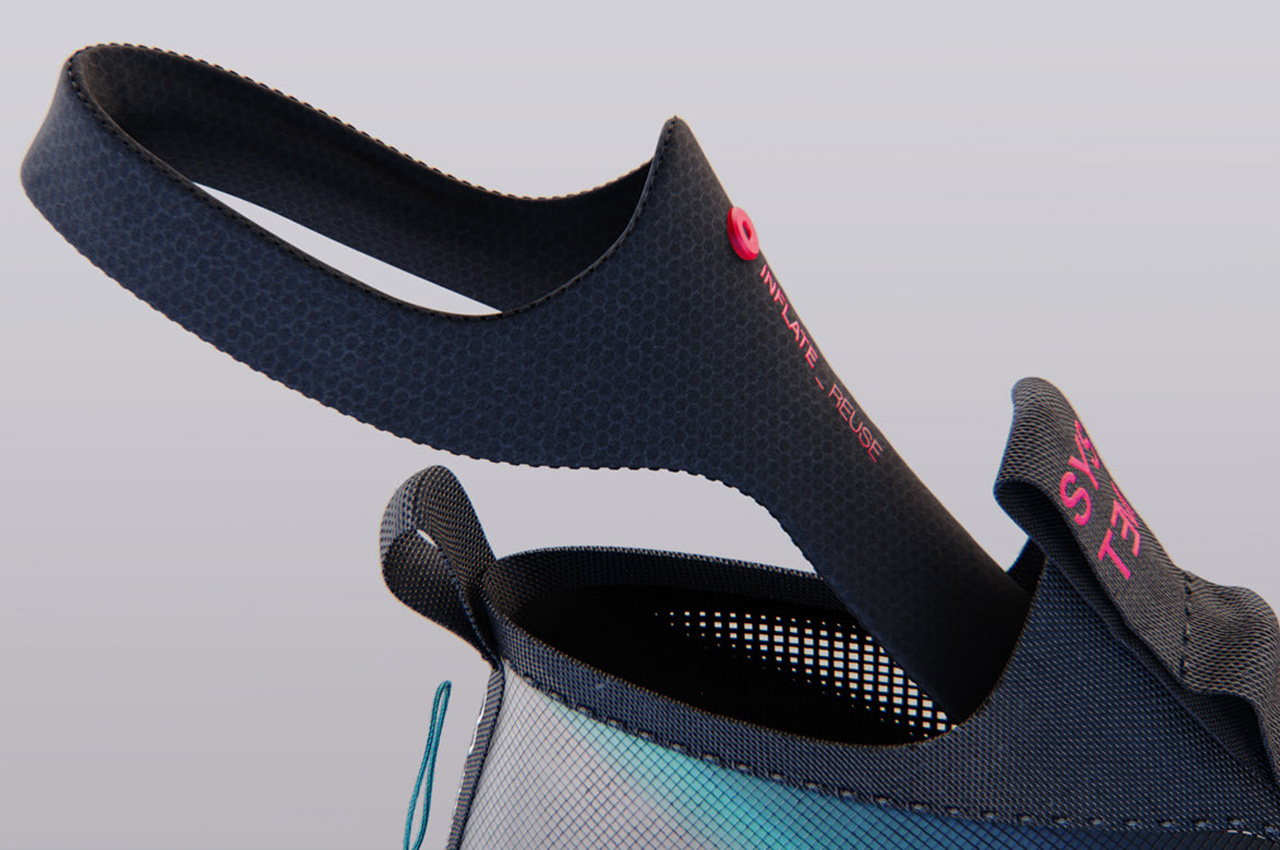

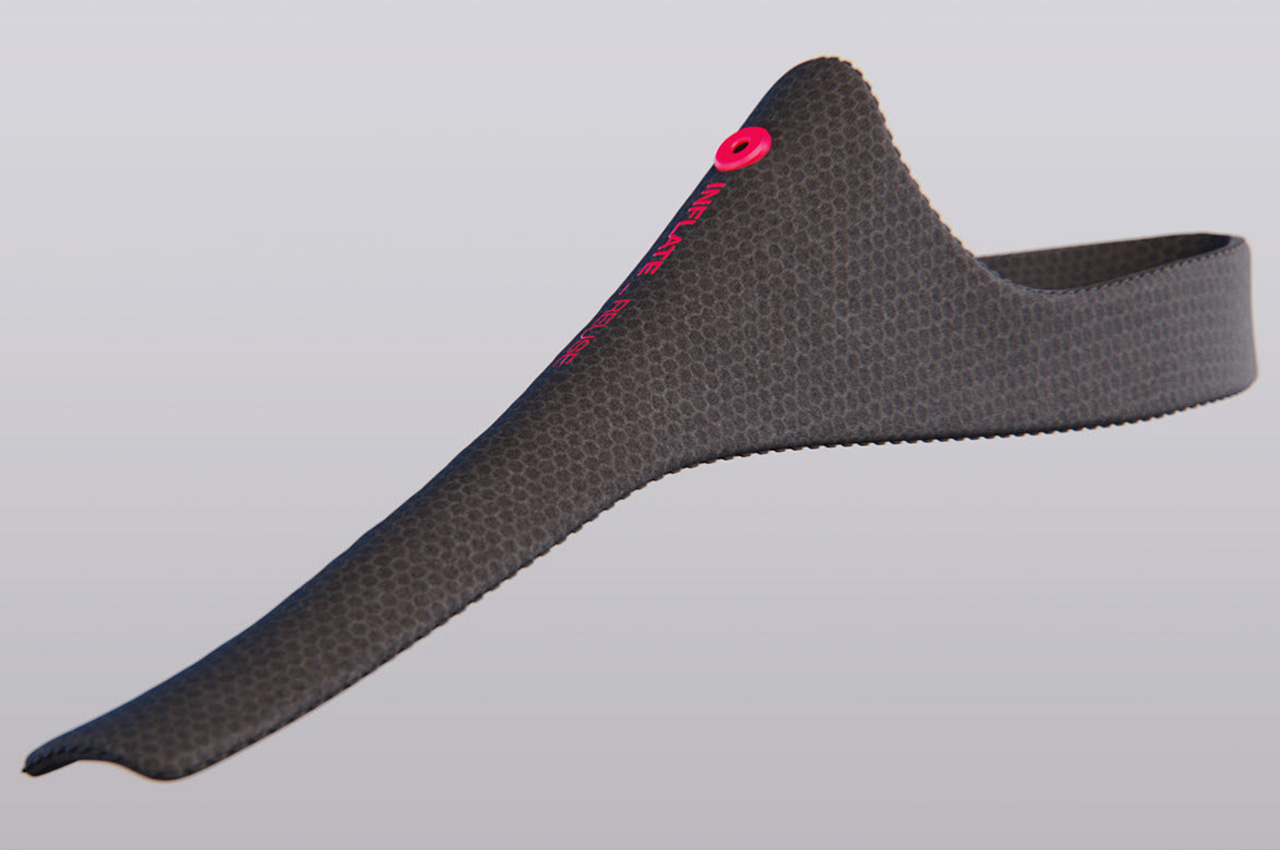

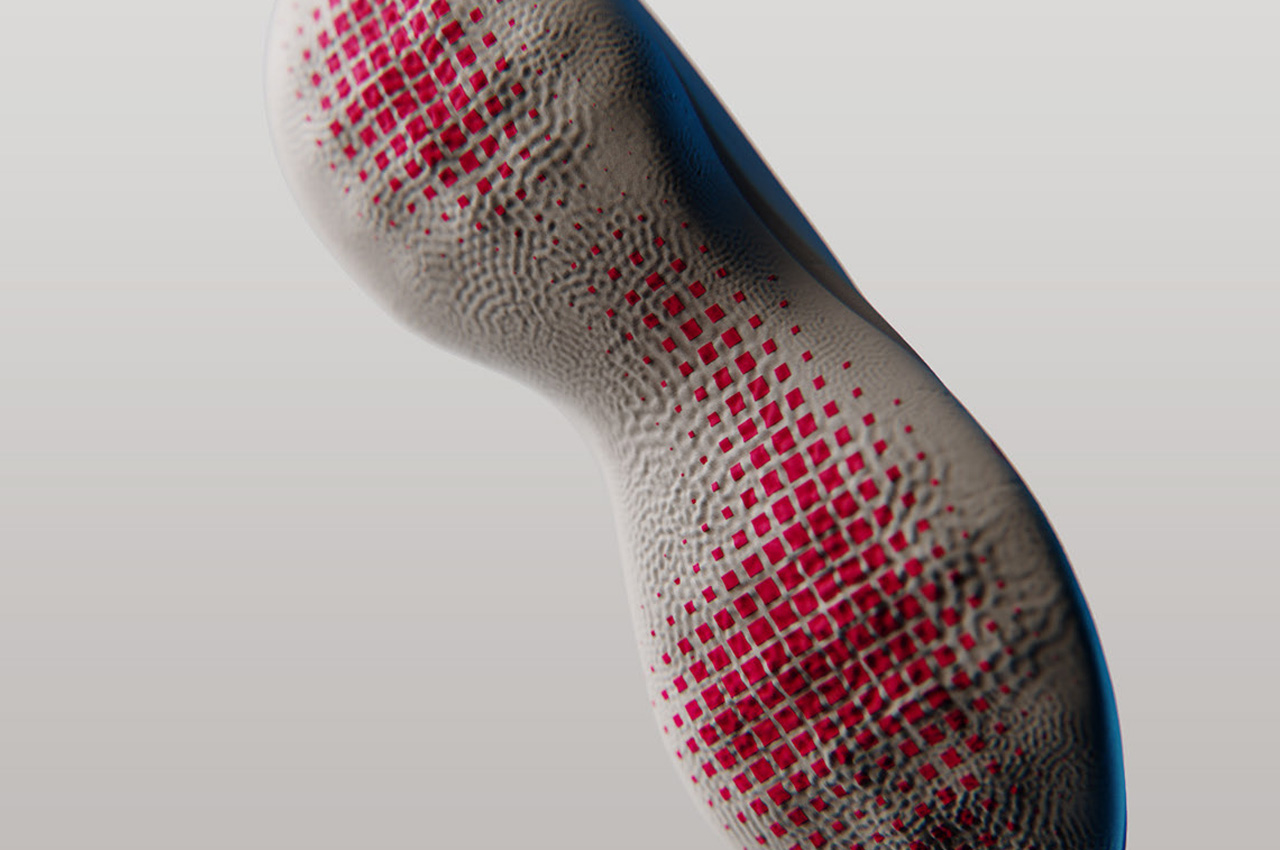

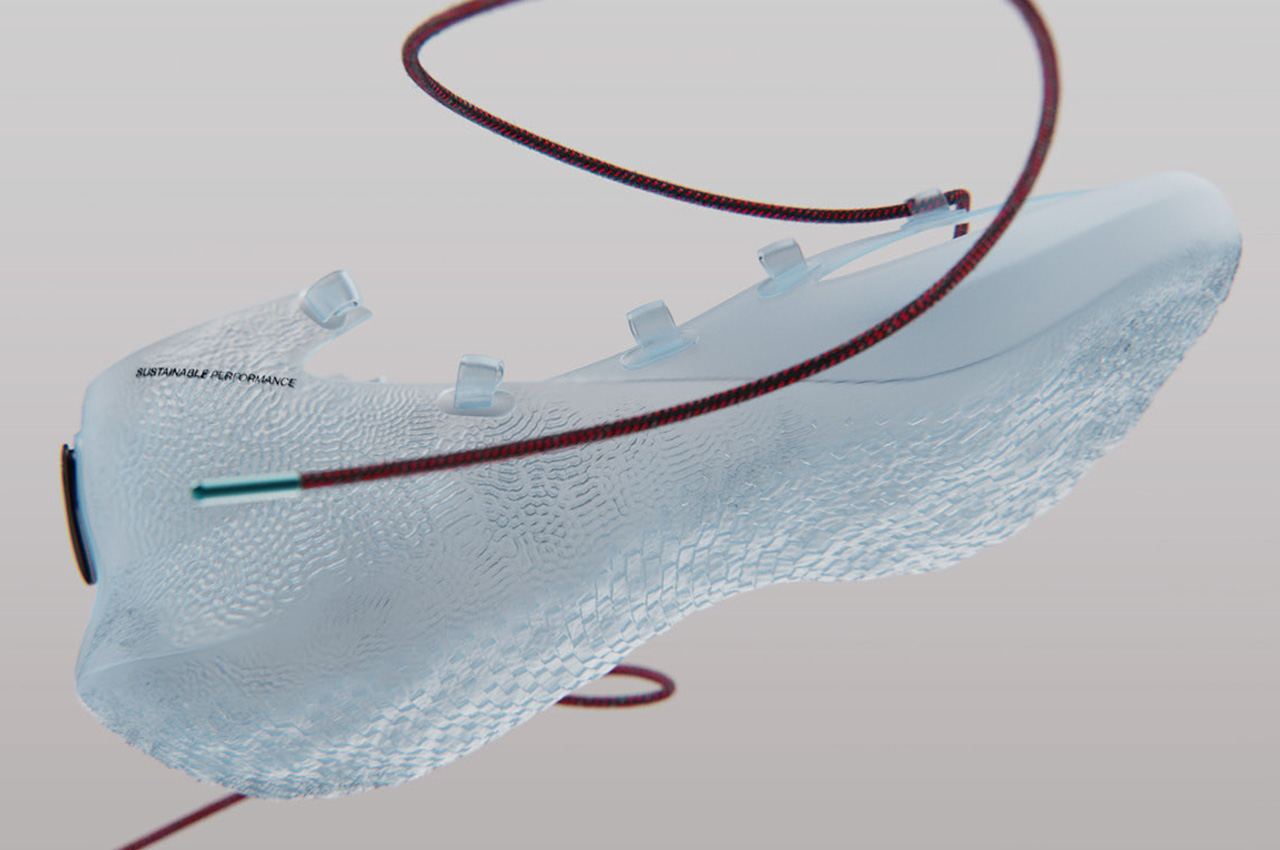

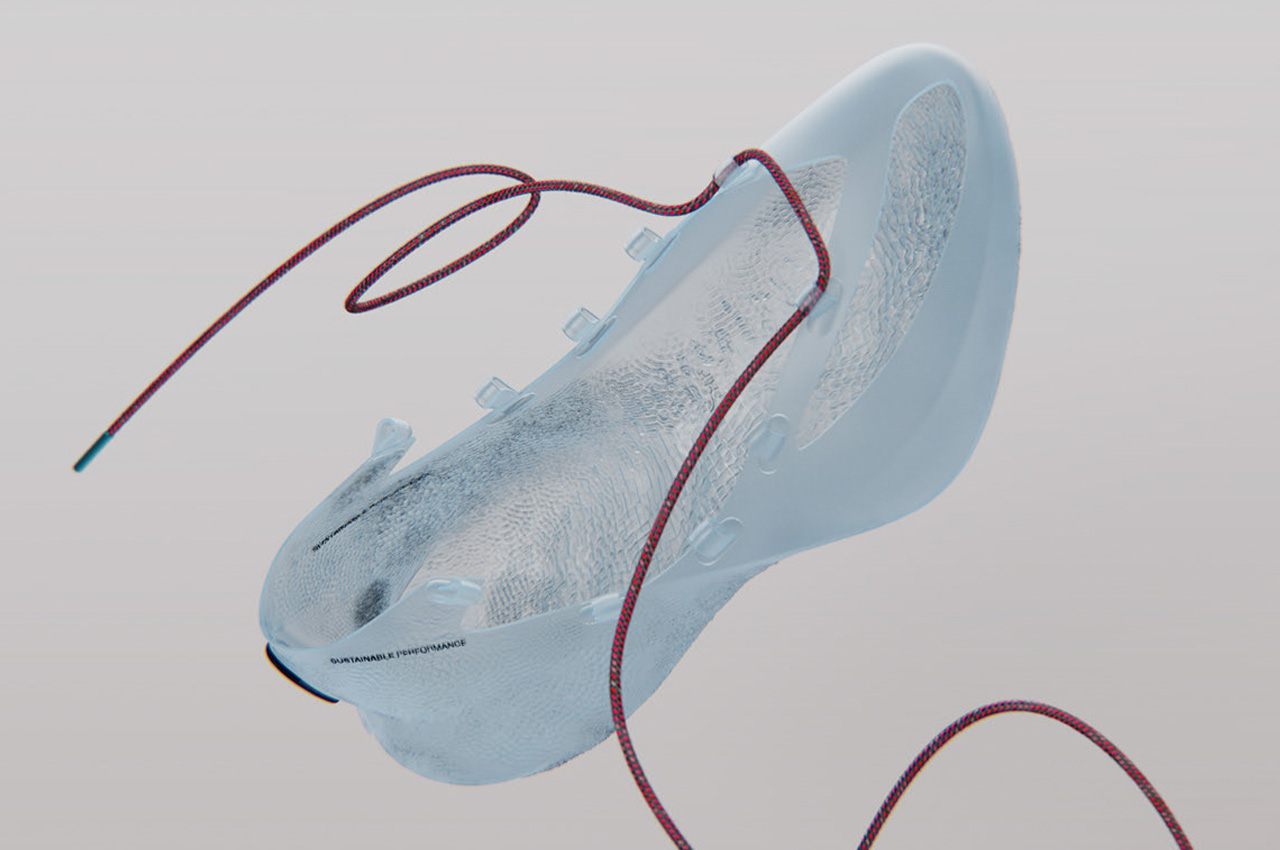

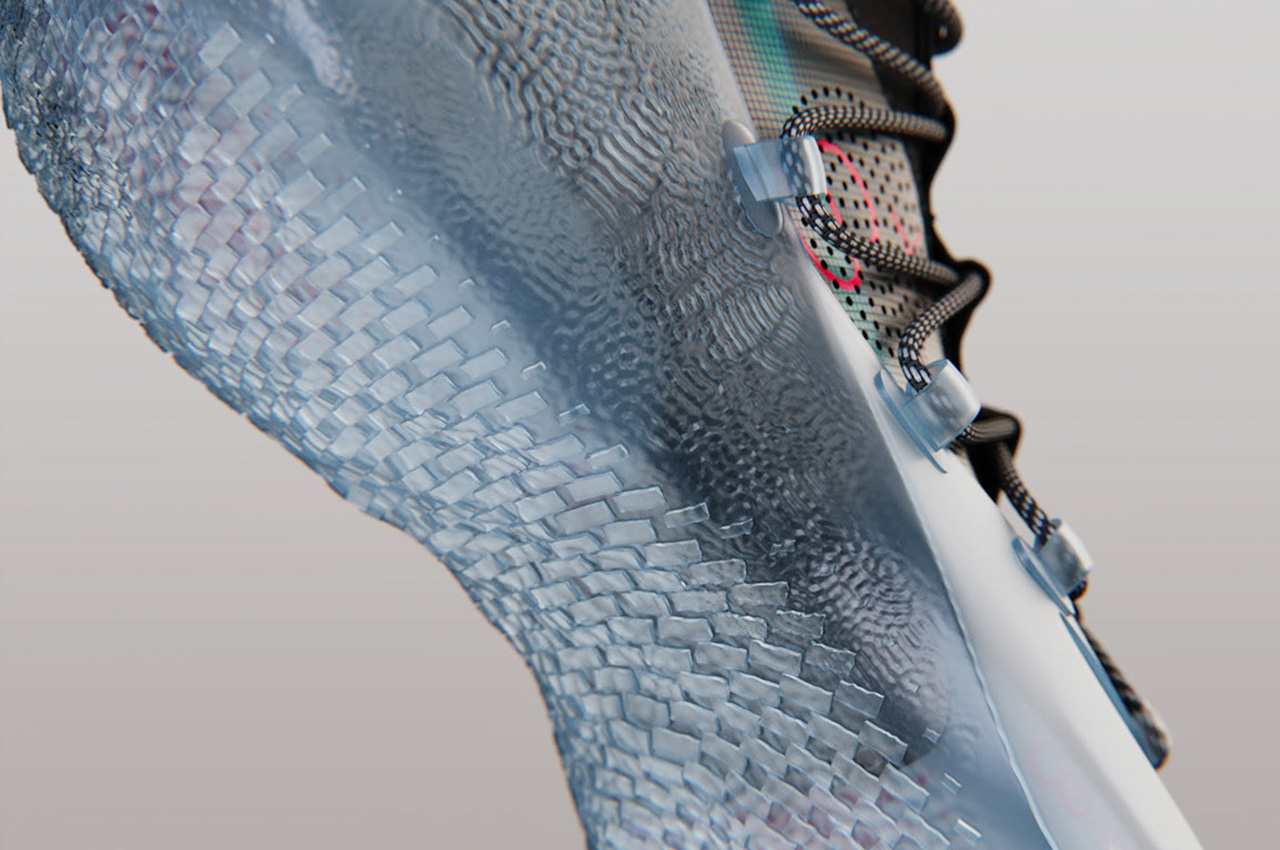

In order to match the requirements of a great basketball shoe, this modular sneaker features a lightweight and perforated upper for good breathability. For comfort, the tongue and ankle areas have inflatable padding, which can be adjusted to need. The removable midsole, forefoot and heel regions come with detailed cushioning, while the translucent outsole wraps around the entire sneaker to act as its skin.

The full package is held together by a cord locking system that fastens the upper, midsole and outsole together without glue. This keeps each part of the shoe practical for recycling at the end of life. So, imagine a scenario where you can replace the shoe parts for the best fit and your style of play on the fly. When some section of the shoe wears out, you can have a new one tailored to perfection and assembled with the existing parts to use again while the waste goes into recycling. This is exactly what the future of the footwear industry we’d want to be realized, and Dennis’ effort is a commendable step in that direction!

Designer: Dennis Johann Mueller