Can you remember a time before 3D printers? If you’re under 30, probably not. 3D printing’s seen quite an explosion since it debuted as a consumer-centric technology with the MakerBot back in 2009. While the technology has existed for a while before that too, the Cambrian explosion that occurred post-2009 made 3D printing an essential part of almost any industry you can think of – Design, engineering, architecture, medicine, aerospace, even concept art.

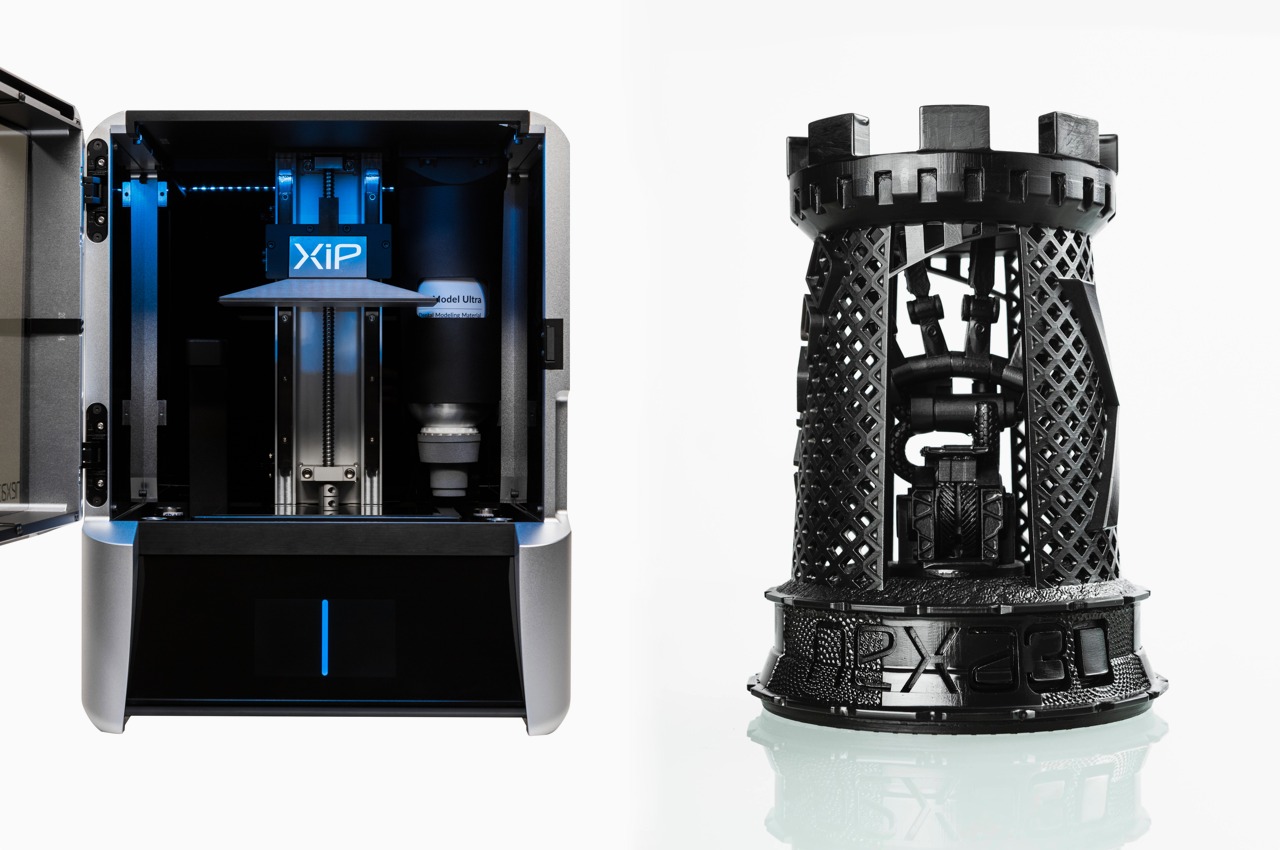

We’ve covered Nexa3D’s XiP Ultrafast Resin 3D Printer in great detail in the past, but today we get to talk to Rob Wiggins, a former Hollywood prop maker who’s worked on massive franchises like Marvel, Star Wars, and Transformers, and even as a contractor for toy and game company Hasbro. Rob now works with the Nexa3D team, helping them design, better, faster, and more efficient 3D printers that can be used by consumers, hobbyists, studios, and massive industries. He created the world’s largest 3D-printed chess set using the XiP, featuring a highly intricate collection of chess pieces that sit on a massive backlit chessboard. The interview highlights Rob’s career journey, his workflow, how he designed the chess set, and why the XiP may just be the most innovative 3D printer ever. Stick around till the end and you’ll even get to know how to improve your own 3D prints, and how to be a concept artist just like Rob!

Want to get your own 3D printed xRook to see what Rob’s (Nexa3D’s) 3D printers are capable of? Snag one here.

Mesh Walls – Mesh walls show an important capability of design for lightweight parts. An element that is nearly impossible with other technologies.

Text Embossed and Engraved – Text printed on XiP is not only legible but beautiful. xRook displays text throughout both embossed and engraved.

Yanko Design: Hey Rob, tell us a little bit about your background and how you came to pursue such an interesting career line!

Rob Wiggins: Grew up in NYC and was a commercial artist, taking any gig I could get. I’ve done paintings, playbills for musicals, comic book covers and fan art. My passion for fan art and pop culture landed me a freelance job working with Hasbro toys, which led to movie studio work and what I do today.

YD: Do you remember some of the most memorable projects you worked on? Anything iconic that we’ve all seen?

RW: I’ve been fortunate to work on many memorable projects. Probably the ones that have been seen the most were several Transformers films including the upcoming Transformers Rise of the Beasts this summer! Some of the unseen work was made for a couple Disney+ shows like last year’s Obi Wan Kenobi show.

YD:. I’m assuming prop-making for Hollywood requires a lot of modeling and 3D printing. What’s your usual workflow been? What sketching and CAD software do you use? Which 3D printer do you find the industry relying on most?

RW: With prop-making speed and efficiency is most important. So, 3D modeling and 3D printing is in a great place right now. Most times my workflow consists of 3D sculpting and 3D sketching with programs like Maya, Blender, or ZBrush right away, bypassing traditional sketching and painting. If and when the need arises to sketch or paint, Photoshop has been my go-to 2D software.

I don’t think the film industry relies on a specific 3D printer “most” in general. There are many 3D printing technologies from FDM to mSLA, and I’ve seen that most prop masters and design teams will use whatever they feel is right for the job at the time. Also, most teams will use whichever 3D printer and print tech (FDM / mSLA / SLS) they are familiar or most comfortable with.

YD: What’s working for Nexa3D been like? How different is the culture as compared to your past role?

RW: Working for Nexa3D has been F-A-N-T-A-S-T-I-C!!! It has been a dream to have access to such amazing technologies. From the unparalleled speed of Nexa3D’s print platforms to the incredible materials Nexa3D provides, to the freedom our CEO has entrusted me with as Head of Creative Services. I could not be happier with the Nexa3D team and culture here at Nexa3D!

The culture here at Nexa3D is very value-centric, in other words, we think about how our endeavors will add value to the end user experience. I’ve found that the culture here at Nexa3D embodies humility and graciousness. People here are very grateful and hardworking!

In Hollywood prop-making, people are definitely hardworking! However, the work can tend to be a bit thankless, and most times you won’t have as much creative freedom, considering you’re working on a pre-determined intellectual property.

YD: We’re in absolute awe of the chess set you created! What was the process like? Did you have a theme in mind? Which software and printer did you use?

RW: Wow, thank you very much!!! The process was a lot of fun, since our CEO encouraged me to let loose creatively. One of my first projects for Nexa3D was creating the Nexarator prop helmet. Keeping that design in mind, the theme I tried to develop for our chess set was matching the detail and complexity of our xRook while helping to showcase some of our new resin materials that we have been eager to release.

The software I used was Maya, Blender and ZBrush. The printer I used almost exclusively was our XiP desktop printer. I also used our NXE 400 printer for some of the larger pieces like our King and Queen.

YD: How long did the entire printing process take? Was there post-processing required after the job was complete?

RW: Oh boy… The printing process was hefty. Considering it also included the 64 tiles of the chess board along with 32 chess pieces and their own multiple pieces/prints. Overall, it was over 100+ prints in 7 days, along with a week to post-process and paint all the pieces.

YD: What benefits do you see with the Nexa3D Ultrafast Resin Printer? Which sorts of products do you find it prototyping better than others? What industries do you recommend the printer for?

RW: I think Ultrafast says it all! Thinking about our chess set. There would be no way I could’ve completed that set in 2 weeks without Nexa3D! Completing a similar project would’ve taken a month or more even with multiple teams helping to print and post-process.

Nexa3D printing technology can be used in prototyping pretty much anything you can think of, with the limits really being your imagination; ok well maybe not printing food or cloth material 😊.

I’d recommend Nexa3D for any industry looking to seriously upgrade your prototyping workflow. Whether it is speed; in realizing your new upcoming or current product in the fastest time possible or bypassing the manufacturing process altogether. No matter what, Nexa3D will have a great solution for your industry.

YD: Do you have any trade secrets for how to get spectacular results from your printer every time? What features of the Nexa3D do you love the most?

RW: Print orientation is my best-kept secret. Knowing how or why to orient a part on the build platform can save you time or make your post-processing way easier. 3D print orientation can also help to minimize supports or enhance your parts’ mechanical/material properties. It all depends on what your project needs. I recommend that everyone take time to research, test and improve their 3D print orientation to find the best results for their project.

With Nexa3D I just LOVE the speed and resin material properties. The resin materials we use here at Nexa3D are the best I’ve ever worked with. Coming from creating a studio maquette that took days to print and was so very fragile, to printing something similar within work hours (6 – 8 hours) that withstood multiple drop tests on a hardwood floor, is like night and day!

Smooth Surface Finish – XiP is capable of smooth surface finish with 50 micron layer height and antialiasing technology for sub-pixel xy resolution.

YD: What are some other projects you’re currently working on?

RW: We’ve got some great projects just on the horizon here at Nexa3D. As with most parts of my professional work experience, I’m not allowed to talk about them until after the fact. But keep a close eye on Nexa3D’s social media outlets and I promise you’ll be among the first to know!

YD: I’m sure many of our readers will be interested in knowing more about your work and how they can become concept artists and prop-makers for Hollywood too! Any tips and secrets?

RW: It’s a very tough industry to break into. If you ever take the time to sit through the credits of most Hollywood productions, you’ll notice you see the same names over and over again in the producers, directors, art department leads, while at the same time you’ll notice new smaller studios (where work is outsourced) names frequently change. Producers, directors and art dept heads tend to stay the same, while a lot of work gets outsourced to smaller studios that bid for work. Your best bet is to build a body of work that will get you noticed and get that work in front of the right people. It’s an intricate balance, being a creative (concept designer/prop-maker) and also networking (sales) with others. But find your niche and be resilient when it comes to showing your work, taking feedback and improving from it. If you’re persistent and don’t give up, something will work out; look somebody greenlit Shark-nado!!

Want to get your own 3D printed xRook to see what Rob’s (Nexa3D’s) 3D printers are capable of? Snag one here.