Constraints form a major part of a designer’s process. Whether it’s constraints based on materials, manufacturing capabilities, technology, or even just budget constraints, designers work well within those boundaries to create the best solutions possible… but what if there were absolutely no constraints? What if everything was left open to possibility? That’s what designer and educator John Mauriello shows with this video, where the sky is practically the limit. Relying on $200,000 printers from Stratasys, and technology that’s so cutting edge that consumers can barely afford it, Mauriello created the wildest set of sunglasses we’ve ever seen. Ergonomics, aesthetics, and design guidelines be damned, Mauriello’s sunglasses are absolute statement pieces, showcasing the themes of earth, wind, fire, and water. Moreover, they explore a set of circumstances that most designers don’t get to explore – a highly elusive ‘what-if’ scenario where money, material, and manufacturing are all open-ended.

Designer: John Mauriello

Prototyper: Stratasys

Before we begin, none of these glasses are designed for the mass market. In fact, they’re experiments that aren’t for sale… but instead, form a core part of Mauriello’s design exploration and education approach. You can follow his YouTube page “Design Theory” to learn more… and if you want to design and print your own frames without shelling out $200,000 for a fancy top-of-the-line printer, scroll to the bottom of the article to learn more about Xometry – a website that 3D prints your designs and delivers them to your doorstep.

A lot of a person’s emotions get expressed through their eyes, and sunglasses hide that. It’s why people wearing sunglasses look mysterious to the extent of appearing ‘cool’. That became the starting point for Mauriello’s ideation. “That’s actually why I came up with the four elements idea,” he said. “I liked the idea of a natural disaster happening around your face, but you still look cool and calm and collected to the outside world. Plus I really liked Captain Planet as a kid…”

To design these outlandish sunglasses, Mauriello resorted to an unconventional design direction that he just wouldn’t get to explore with a client paying for his industrial design skills. It involved a lot of sketching directly in VR using Gravity Sketch, before taking the templates into Houdini to actually simulate effects like fire, wind, water, and earth. For Fire, Mauriello experimented with flames, embers, and sparks before settling on a combination of red flames encased within clear flames. It honestly looks like a fire inside the clear spectacles is causing them to melt.

The Earth sunglasses are pretty self-explanatory, and come with a cracked surface that looks like chiseled rock formations. Unlike the Fire sunglasses that have an almost sinister aesthetic (the kind you’d see on a supervillain), the Earth glasses have a stable, grounded, rectangular form factor that’s made a tad bit more interesting by the cracks in its surface.

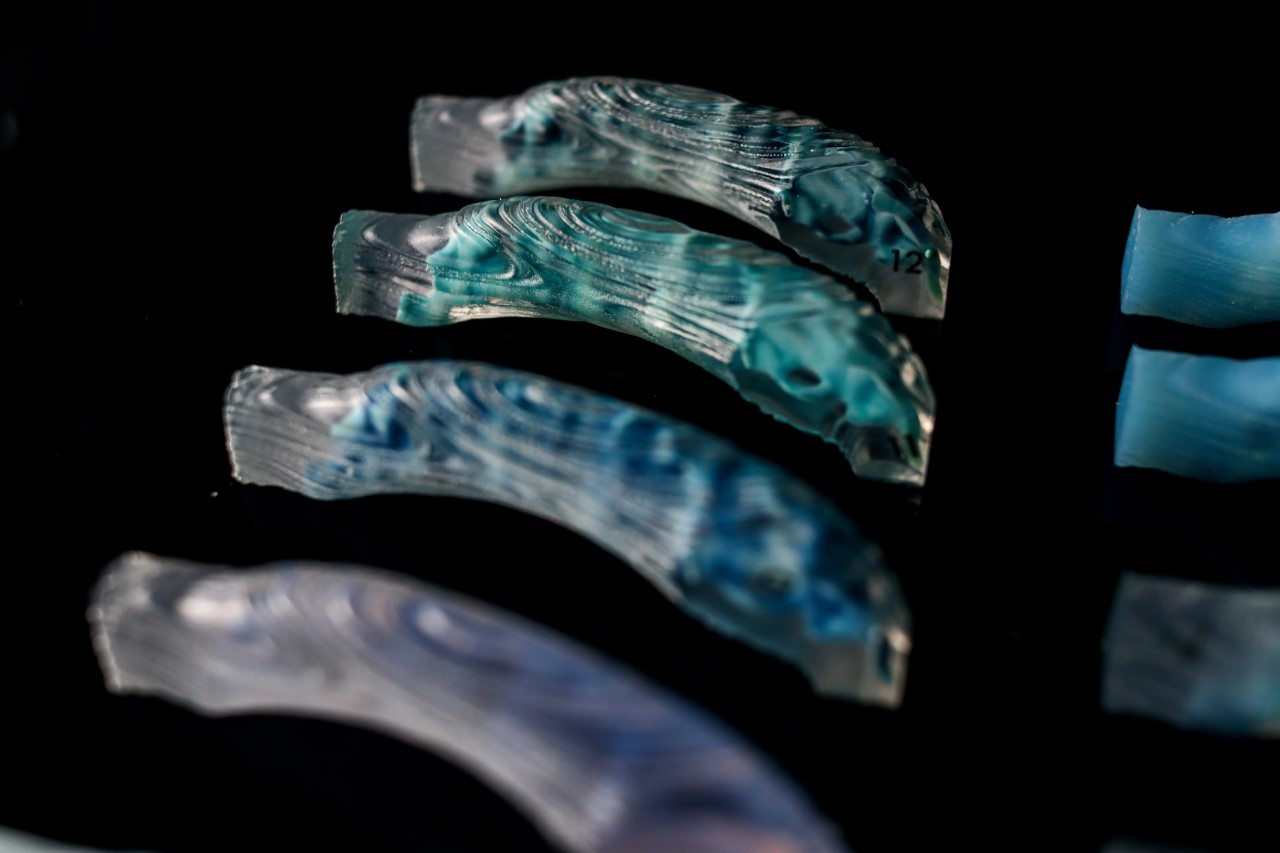

The Water sunglasses have a bubble-like aesthetic to them, with liberal rounded edges and forms; and instead of relying only on simulations, they use a bit of AI-generated art too. The splashes inside the clear frames were made in Houdini itself, but the colors and textures on the splashes were generated using OpenAI’s DALL-E 2. Rather than taking stock images, Mauriello sought to create his own, giving the glasses an added layer of uniqueness.

The Wind sunglasses too use AI-generated textures in the colored elements of the frames. The colored elements, designed to look like wisps of smoke, are trapped in a clear frame that has an aerodynamic shape, with ribs running along the front that looks like a wind-tunnel test come to life. Look inside and you see these incredible wispy forms inside, looking like the glass marbles we played with as kids. Creating this without 3D printing seems downright impossible.

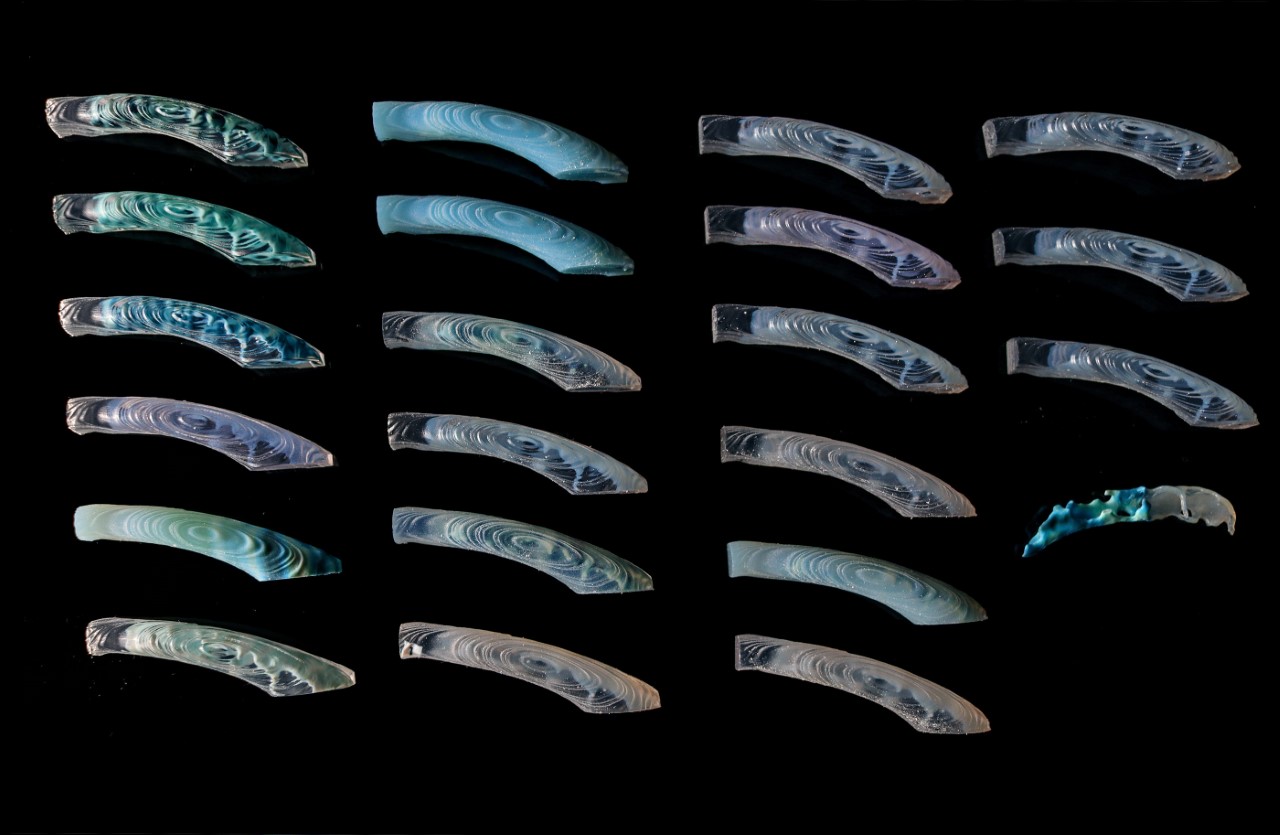

Mauriello was approached by Stratasys, who let him use their J55 printers to build out designs. The J55 is the company’s high-end full-color multi-material printer that prints in ‘voxels’ instead of sliced layers. This allows the printers to meticulously build designs with multiple materials, finishes, textures, and colors all in one stretch – a feature that was integral to Mauriello’s project.

The J55 also allowed Mauriello to build out multiple samples in one stretch, giving him the ability to test out colors, finishes, and other details. Mauriello printed multiple variations of each element, looking at colors, transparency, and overall finish to help him tweak his own models. “You can experiment with a huge range of ideas and one of them is likely to be what you want,” he explained.

Once the samples were ready, Mauriello had them fitted with lenses to complete each sunglass. The glasses don’t have hinges on them, and are unibody (so they can’t be folded), but they are absolutely wearable, and Mauriello even got feedback from a pro eyewear designer on the forms and the overall design language of each elemental sunglass.

The entire project was a collaborative effort between Mauriello and Stratasys, who were kind enough to loan their state-of-the-art multi-material printers to him to showcase their overall capabilities. If you want to make designs just like these, Stratasys does offer a ‘Manufacturing On-Demand’ option that lets you generate an instant quote based on your parts. Alternatively, companies like Xometry have a global network of over 10,000 CNC manufacturers, 3D printers, molders, and other equipment that you can access, for everything from 3D printing to CNC machining and even mold-making. Envisioned to be just as easy as ordering a product online, Xometry lets you upload your model onto their Instant Quoting Engine and have the part delivered to your doorstep in a matter of days. Click here to know more!