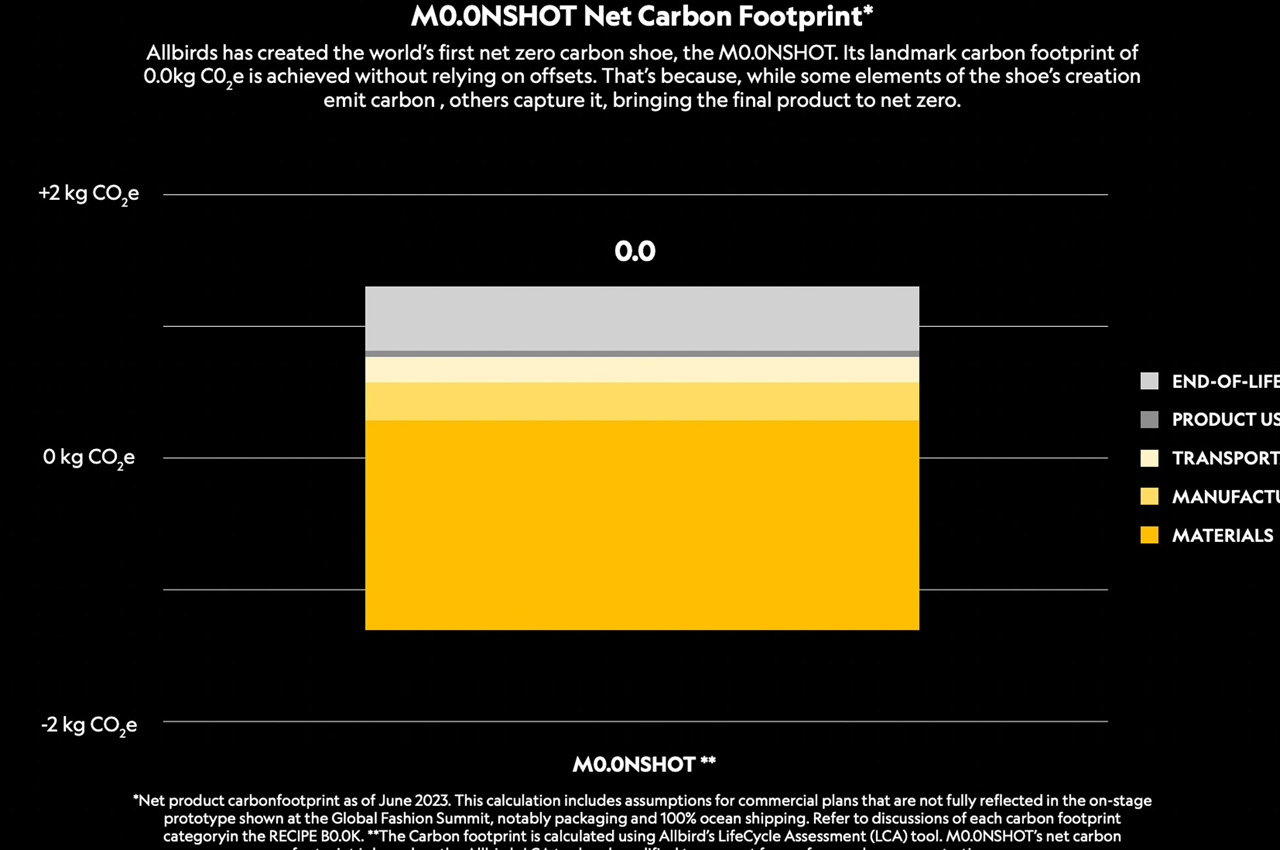

A couple of months ago Allbirds announced the M0.0NSHOT – the world’s first net carbon shoe. Although there are quite a few net carbon shoes out there made from traditional and natural materials, this shoe is the first of its kind in the commercial shoe industry. The minimal, all-grey sneaker is set to have a carbon footprint of net 0.0 kg CO2e and is supposed to be one of the most sustainable mass-produced shoes we’ve seen till now! The shoe was announced in March, but it was finally unveiled at the Global Fashion Summit in Copenhagen on June 27th, we’re quite excited to dive deeper into it!

Designer: Allbirds

The Moonshot is an interesting-looking woolly sock-style trainer that features a bioplastic sole, and an upper made using regenerative wool. The wool was produced on a regenerative farm in New Zealand, which employs sustainable land management practices to ensure it captures more carbon than it produces. “Regenerative wool was a critical pillar of helping us reimagine how products are designed and made through the lens of carbon reduction,” said co-founder Tim Brown. “To me, the currently untapped opportunity for naturally derived, net-zero products is the future of fashion.”

Quite interestingly, the company has open-sourced the design and manufacturing process behind Moonshot with their ‘Recipe B0.0K’, which provides detailed information on the materials, manufacturing, transportation, end-of-life, and carbon footprint calculation behind the shoes. It is an excellent initiative to encourage and motivate the production of sustainable footwear, by sharing their secrets with other manufacturers, and quite literally simplifying the process for them. “It is also about ushering in a new age of ‘hyper-collaboration’ across brands and industries to share best practices, build scale for all parts of the supply chain, to reward growers and lower costs,” Brown continued.

The high-top design of the shoe and its cozy bootie-sneaker style are respectful of AllBirds’ signature style, to maintain and strengthen the connection with the company’s fan base. The carbon-negative regenerative wool upper is complemented by a carbon-negative bio-based midsole foam made using sugarcane and created via supercritical foaming. The logo was made using methane-capture bioplastic through a partnership with Mango Materials. And the packaging for the shoes was produced from sugarcane-based polyethylene, a carbon-negative material that cuts down on the weight and space needed for transportation. All in all, the impressively sustainable sock trainers seem to be paving a new path in the world of footwear!