Passive RFID tags, like the ones attached to products in stores for easy checkout, are generally manufactured using a mixture of metal and circuitry to form the tag’s primary parts: a microchip and an equally microscopic antenna. These bits work together to store and communicate information to a nearby RFID reader, and they’re decently cheap to mass-produce, only costing around $0.10 in materials per tag (according to the International Association of Information Technology Asset Managers in 2021).

Still, the gross cost of mining and producing large quantities of metal and circuitry components adds up over time, and due to the nature of those materials, regular passive RFID tags have nowhere to go — well, other than the trash bin — once they’re pulled off of the products they’re designed to protect.

According to PulpaTronics, the developer of a revolutionary all-upcycled paper RFID tag design, over 12 billion RFID tags are manufactured per year, often for single-use purposes, after which they end up in landfills. Founded by a group of four students at the Imperial College London’s Dyson School of Design Engineering, the PulpaTronics team is already making waves (and winning multiple awards in sustainable design) for their ingenious paper RFID tag design, which eliminates metal from the manufacturing process entirely.

Designer: Chloe So, Barna Soma Biro, Rui Ma, Jingyan Chen (via PulpaTronics)

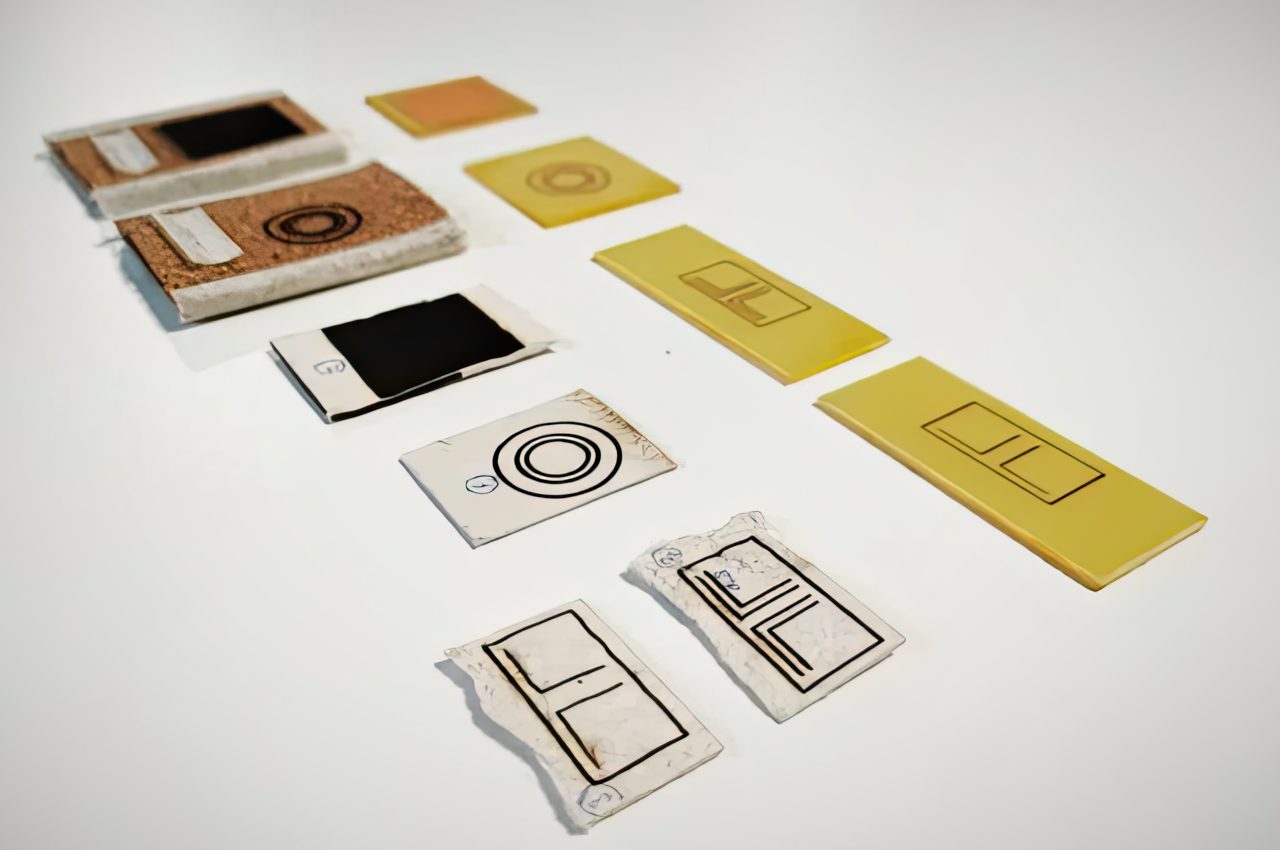

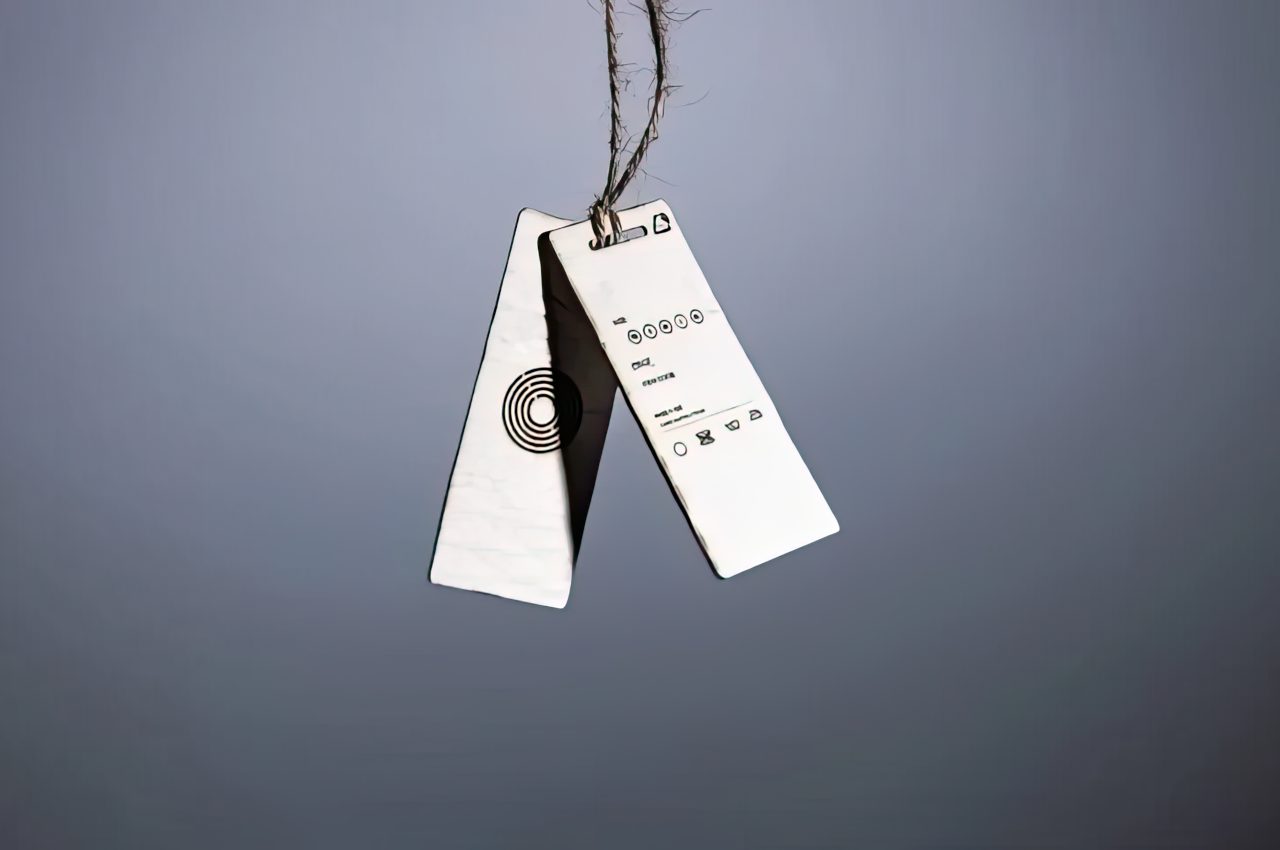

PulpaTronics’ all-paper RFID tags store information geometrically, using a laser to imprint a “conductive layer of carbon material” directly onto paper materials upcycled from the recycling bin and from the trash. According to the James Dyson Award organization, the team also experimented with other materials, like wood and cork, before ultimately landing on paper. The result: an RFID tag design that is twice as cheap to mass-produce as other RFID tags, while contributing 70% fewer CO2 emissions.

What’s interesting about the team’s design is how they was able to reinvent each part of the RFID tag, including antennae, without any metal whatsoever. Once again, it’s all just paper with a little bit of carbon sketched on top; the geometric shape of the carbon layer is what gives the RFID tag design its conductivity and its ability to transmit information to a nearby reader.

If PulpaTronics’ new tag design goes into mass-production, that could apparently save “20,000,000 kilograms of CO2 annually” per 100,000 items using the design. In any case, this is a sizable win for sustainable engineering — further proving that it’s possible to replace metal and other scarce and non-degradable materials with easily-sourced alternatives.