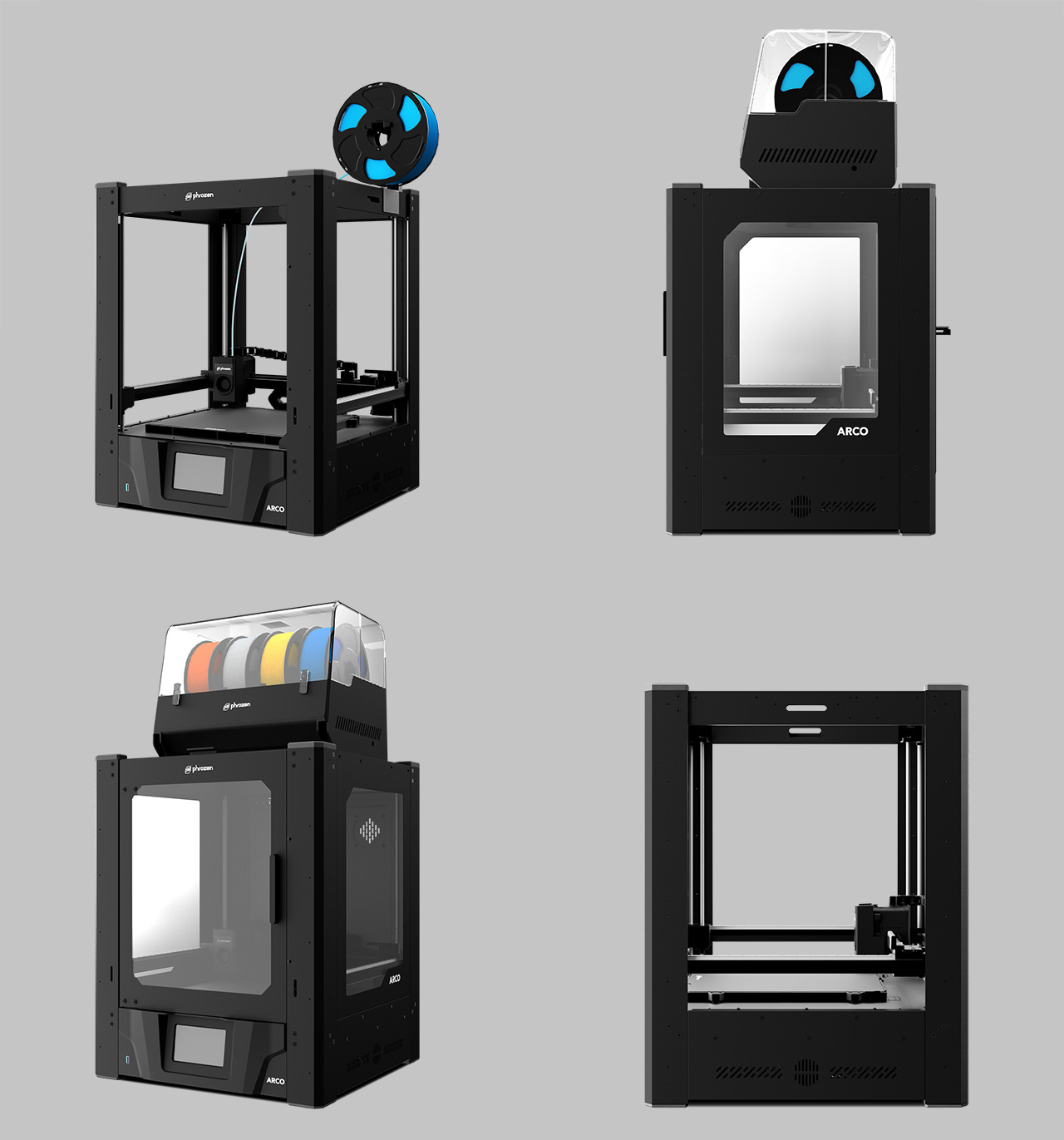

Set to go head to head with other leading FDM 3D-printing brands, the Phrozen Arco boasts a max print volume of 300x300x300 mm³, an acceleration of 30,000 mm/s², and a top speed of 600mm/s. Sure, that sounds like a whole bunch of numbers… but it translates to three simple words – Bigger prints, faster. Unlike its other competitors, it also comes with a Chroma Kit, empowering users with multi-filament printing capabilities that let you print in vivid color.

Designer: Phrozen Arco Team

Click Here to Sign-up Now: Early Access Ends Soon

Phrozen recently announced its first-ever FDM printer, the Arco, which will head to Kickstarter at the end of this month. Having built a solid reputation selling some of the finest resin printers, Phrozen hopes the Arco will set the gold standard for extrusion-based printing, which seems to be picking up as more and more users/creatives/businesses begin integrating 3D printing into their workflow.

Phrozen Arco driven by its Chroma Kit (multi-color AMS), introduces up to 16 colors for your creations. No coating required—now, print vivid, colorful models effortlessly.

On paper, the Arco’s specs put it in the upper echelon of consumer-grade 3D printers. The massive 300x300x300 mm³ build volume lets you print large-scale models without necessarily needing to slice them into smaller, more manageable bits. Larger models, however, are notorious for taking more time to print, but the Arco’s 30,000mm/s² acceleration and top printing speed of 600mm/s make it a worthy contender for being one of the fastest consumer-level 3D printers out there. The Arco is based on Klipper’s 3D printing firmware too (with more third-party collaborations in the pipeline), allowing it to benefit from its open-source nature and improve over time through OTA updates.

Simultaneously print multiple sets or larger models-unleash your imagination with the largest volume color 3D printer.

The speed factor isn’t just a question of cranking up the motors on the X and Y axes, it also requires precise engineering to ensure the filament flows at exactly the right speed (otherwise you get warped, bad-quality prints). To achieve this, the Arco boasts dual 18 mm extruder gears and a 9.5:1 reduction ratio HGX extruder, along with a patented direct extrusion path that cuts the distance between the extrusion gears and the heat source that melts the filaments. Paired with Arco’s patented cooling systems, this allows you to print perfectly with tricky materials like TPU, or achieve ultra-fast prints with traditional filaments like PLA. The external part of the printer is reinforced too, with a stationary bed supported by 4 thickened stands that reduce vibrations that cause those notorious ‘layer lines’ during high-speed printing.

Phrozen is also allowing users to add a Chroma Kit to their Arco. While traditional printers only have a single-spool setup, the Chroma Kit (Phrozen’s self-developed automatic material system) lets you mount multiple spools of filament, supporting 4-color 3D printing at present, upgradable to 16-color prints in the future by connecting more Chroma Kits following upcoming OTA updates. The Chroma Kit works as a dry storage unit for your extra filaments and relies on a series of motors and sensors to automatically swap out old filaments and feed in new ones during prints.

All this is encased in what Phrozen describes as a robust, reinforced outer structure that ensures minimal tolerances for better quality results. Each Arco is also accompanied by a Pentashield – made of acrylic and metal panels – that helps encase your printer in a protective enclosure, reducing noise as well as maintaining optimal print temperatures. PIXUP, Phrozen’s own slicing software, helps load and prepare models for printing too, and their dedicated model library lets you easily choose (or even sell) print-ready models, creating a community that truly helps set 3D printing apart from any other manufacturing industry!

Click Here to Sign-up Now: Early Access Ends Soon