Box cutters, or simply cutters, are a common sight in any office or workshop. The basic design hasn’t changed much over the years, with the most common style using a long segmented blade where you can snap off a section when it has become dull. This simple design, almost like a stackable “push-point” pencil, offers an efficient mode of operation, but not without its drawbacks.

One big problem is that the actual section of the blade you can actively use might be too small since you can’t push it out too much or it will snap and break if you apply too much pressure. A single, unbroken blade might still be the most stable design, but it’s also the most wasteful. This concept tries to find a middle ground by employing a rather unorthodox design for a box cutter.

Designer: ZOZ Works

Given how you need to have a secure and firm hold on a cutting tool, you might presume that you need a large unibody handle design. As small EDC knives and cutters have proven, however, that’s necessarily the case. And just because something comes in parts that can be separated doesn’t mean that it will be structurally unsound and unreliable.

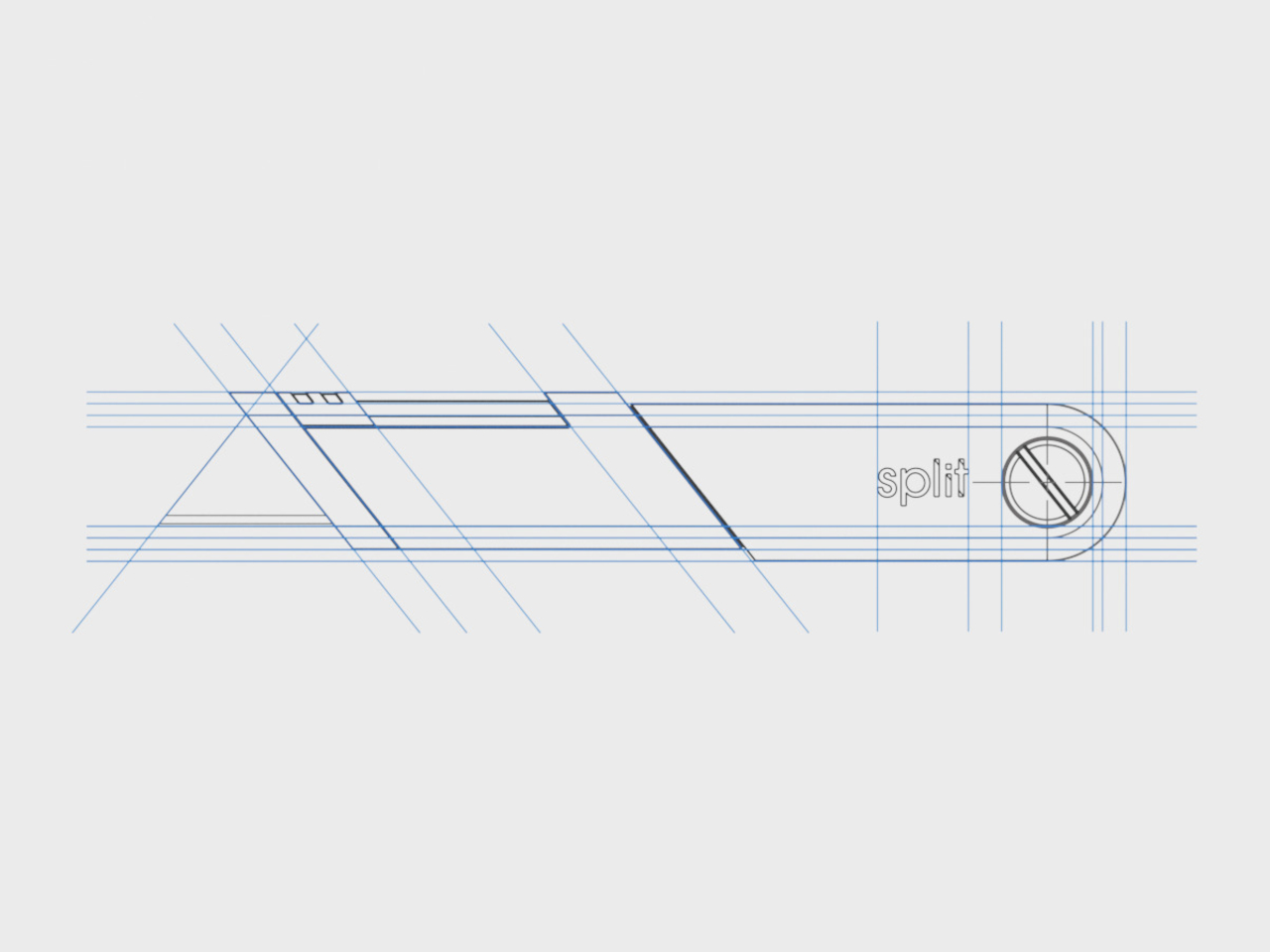

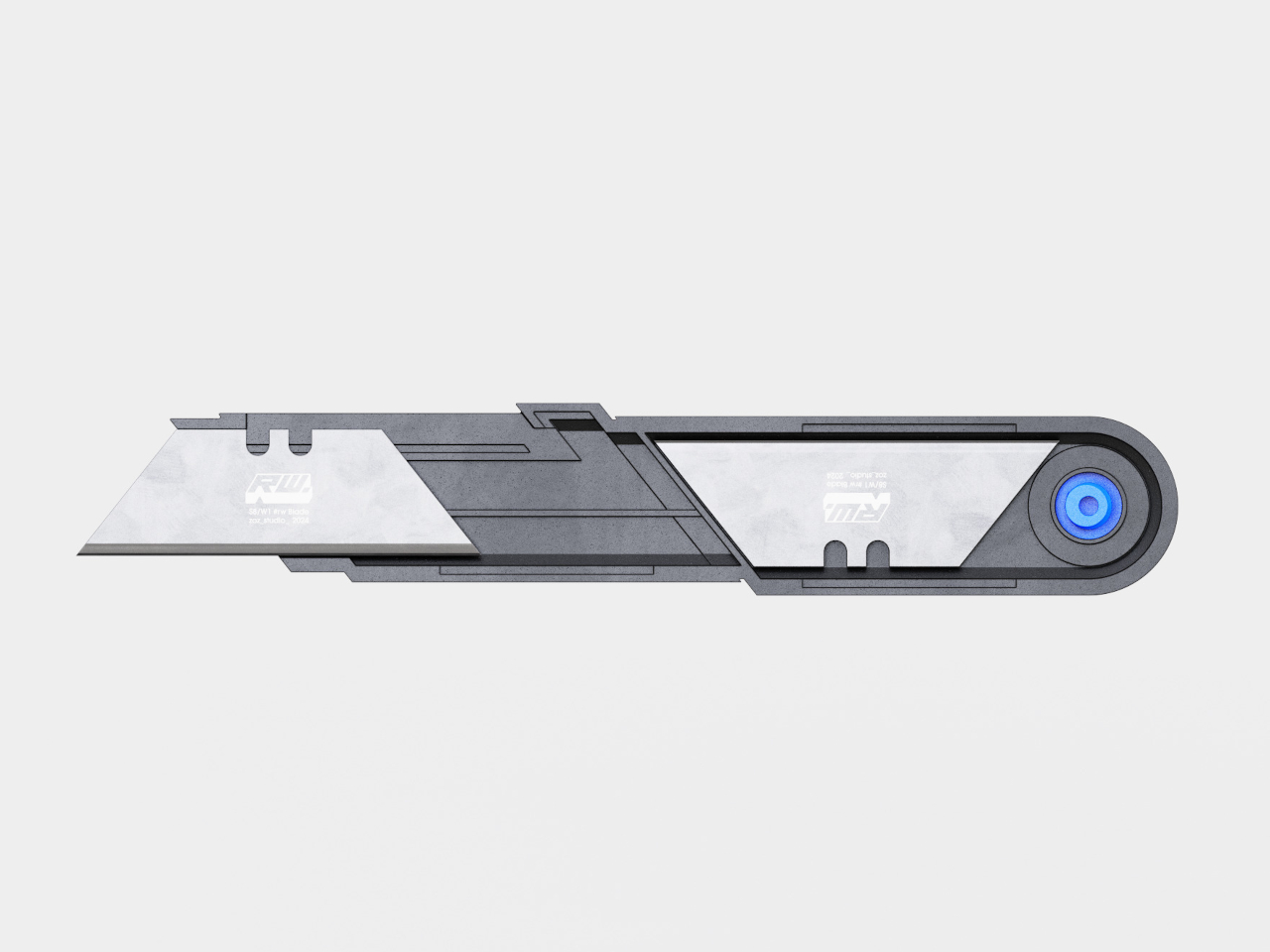

Split is a concept that uses these ideas to design a cutter that can split into two halves. It isn’t just a gimmick, though, as the upper half houses the currently “active” blade while the other half holds spare blades or blades you have removed but have yet to throw away. It suggests a box cutter that’s still self-sufficient yet more efficient than current designs, at least in theory.

The cutter still uses a retractable mechanism to deploy the blade, but you will have a larger blade to work with. This means you can push it out further without worrying that the blade will break along its segment when applying force. At the same time, you still just have a short blade, so you don’t need to throw a long blade should it become dull.

The Split box cutter concept houses those replacement or used blades in the lower half. The concept doesn’t exactly mention it, but you might be able to store more than one blade there. The blades seem to be clamped down to keep them from moving inside, and a simple screw loosens or tightens the cover. The one disadvantage to this design is that you might need some other object or your fingernail to turn that screw.

The cutter concept has a rather asymmetrical design when the two halves are connected, with one part extending a bit further than the other. This imbalance almost creates a jimping part or at least a finger rest, allowing you to hold the cutter with a firmer and more confident grip.