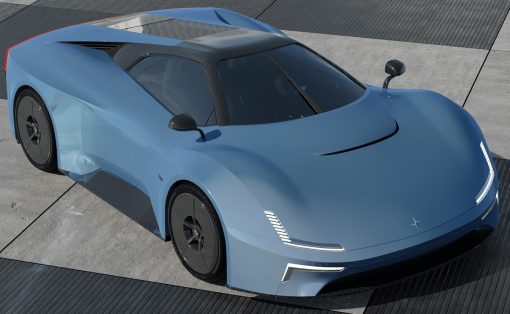

Why use extra material to make a metal or carbon fiber body for your car, when your chassis can BE your car’s body instead? Designer Maitreya Dhanak’s absolutely wild Lotus Evanora Concept treats the chassis as a design element, resulting in a speedster that’s both visually and physically lightweight. Not to mention the fact that it looks like an exoskeletal beast!

Designer: Maitreya Dhanak

Christened ‘Evanora’ or Greek for ‘gift from the gods’, Dhanak’s concept falls in line with Lotus’ tradition of naming their vehicles beginning with the letter E. Dhanak’s approach towards designing the car deviates from the standard practice of taking a top-down approach. While most car designers have an internal framework pretty much ready, they always start with the outside and work their way in. Dhanak, on the other hand, designed an outer structure to complement the inner structure. The skeletal bodywork you see was designed to clad just the chassis, resulting in an aesthetic that’s quite literally as minimal as it gets. The results speak for themselves – since the body (made from carbon fiber) covers just the chassis and nothing else, it uses lesser material, and naturally creates pockets for air-flow, creating a car that’s light and airy both in perception and in reality!

“The support structures are inspired by the shape of branches of trees”, Dhanak says. “These form a network of support structures that help in keeping the weight of the car low and increasing structural rigidity while being visually unique as well.” In turn, they guide airflow in a way that helps cool the car as well as create the downforce necessary to hit higher speeds.

Dhanak’s concept is quite reminiscent of the HV-001 by Ayoub Ahmad, which featured a similar-looking generative-designed stylized chassis. It feels almost like a trend in the making, where cars can now rely on advanced algorithms and materials to achieve an incredibly aesthetic bare-basics look that tends to discard all that’s unnecessary, shedding weight and looking leaner and meaner in the process!