3D printing is often relegated simply to hobbyists and small-time designers. Given its size limits, architects and interior designers haven’t embraced the technology overwhelmingly yet – but fashion brand PINKO is looking to use the technology to create some of the most unique retail spaces ever. Located within the Fiumicino airport, this outlet boasts an interior facade made entirely of 3D-printed modules joined together. The space looks like living tapestry, as the walls have hypnotic depth to them.

Designer: External Reference

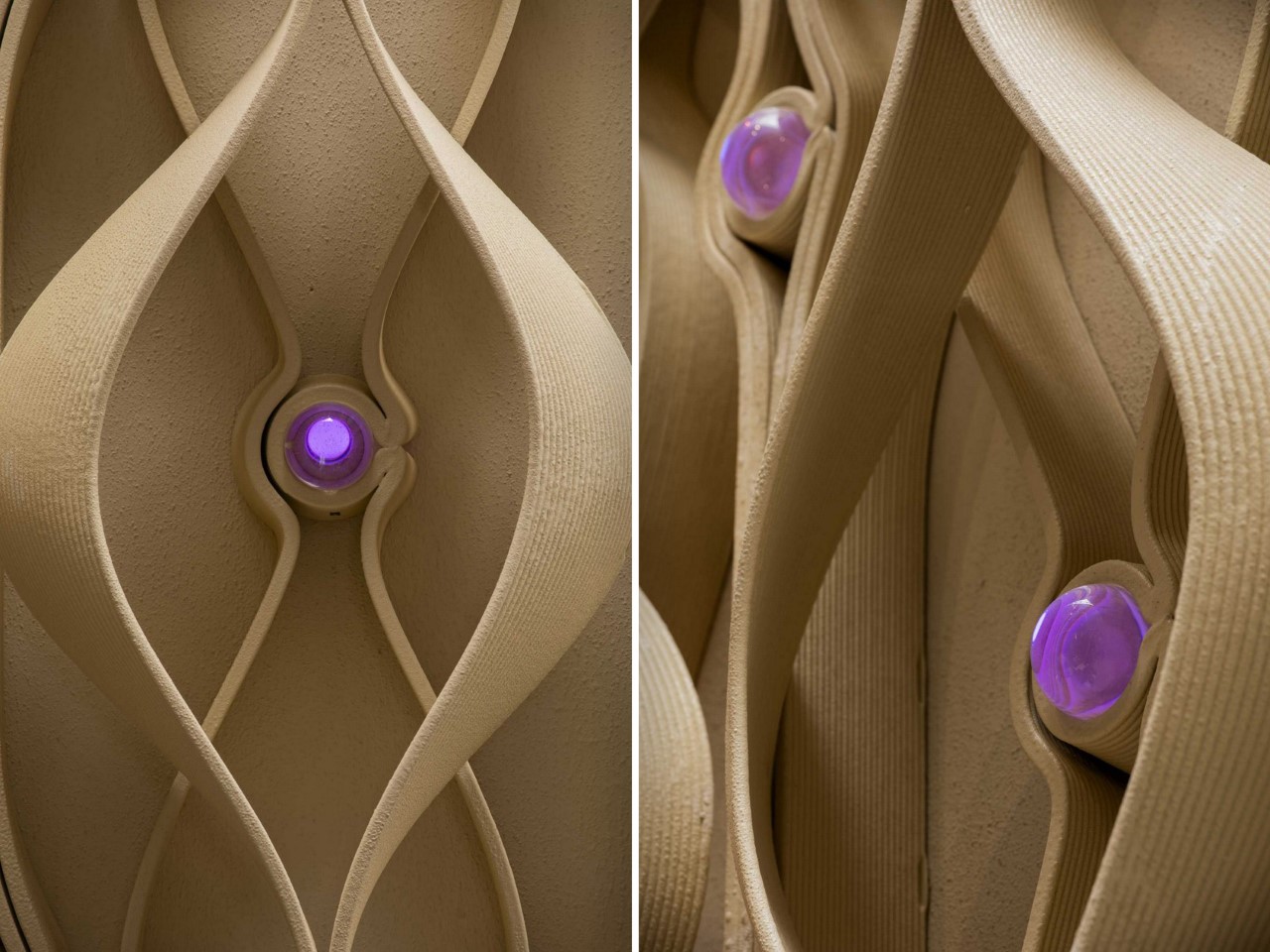

Inspired by the brand’s iconic swallows and the intricate details of textile fibers, the design translates into a “skin” that wraps the entire shop. This textured layer is a marvel of engineering. It’s composed of two overlapping “threads” that begin with a simple, linear arrangement before morphing into a complex, swirling pattern. This intricate design adds depth and a captivating richness to the space.

The “threads” cleverly intertwine with the display shelves, creating a seamless integration between form and function. Glass shelves highlight the handbags, while the central area boasts coat racks that echo the color scheme of the threads, showcasing the garments. The final part of the store features a large mirror, adding a touch of spaciousness…. but the magic doesn’t stop there. Embedded within the 3D-printed cladding are programmable luminous glass spheres. These spheres create dynamic light effects, transforming the atmosphere and injecting a touch of sophistication. The result? A retail space that transcends its purpose, evolving into a dynamic and ever-changing setting.

The monochromatic color palette further underscores the design’s brilliance. The neutral tones create a versatile backdrop that complements the clothing on display, fostering a contemporary and elegant atmosphere.

The complexity of the design demanded an innovative approach to production. To achieve the desired form, prototypes were created using a novel technique where robots 3D printed directly onto custom-made molds. This method allowed for precise control and the creation of a truly unique design element. Each wall panel was printed out of PIPG, a polymer composed of 70% recycled PET-G, demonstrating a commitment to eco-friendly practices without compromising on quality.