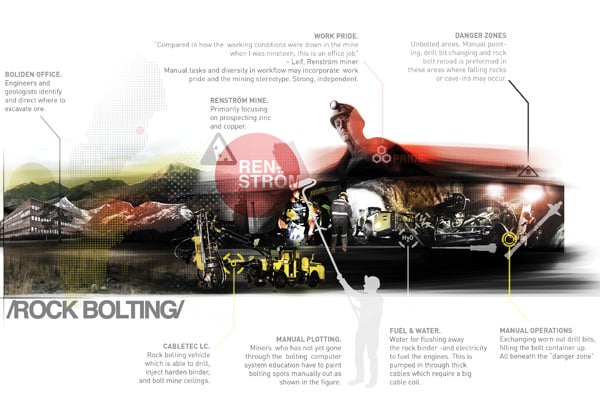

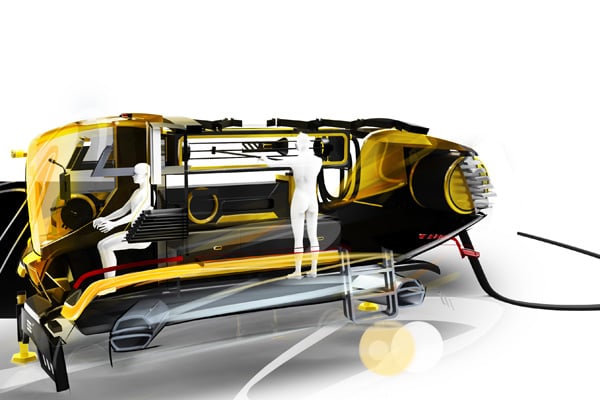

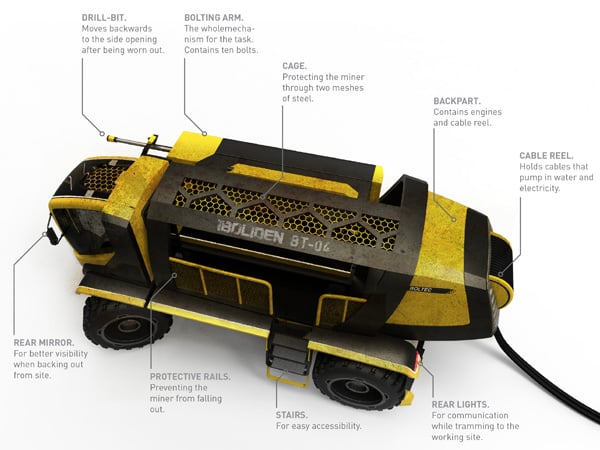

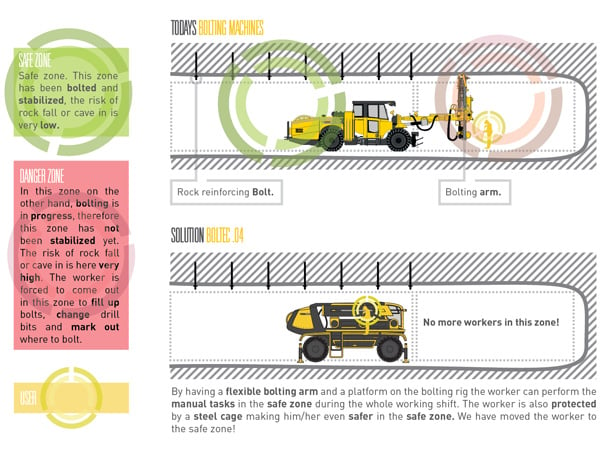

Miners are under great risk when they undertake a procedure called bolting; a way of preventing rocks falling or ceiling collapse. The usual way is to use bolting rigs (bolting machines) that drill and screw in 3-meter long bolts in the mine tunnel. However while doing this, the miners also get exposed to unbolted (not reinforced) ceilings while executing manual tasks. The Boltec .04 is a bolting rig that adds an extra protection.

The vehicle works as a second helmet by letting the user accomplish all manual tasks that the bolting procedure requires protected by the rig and its steel cage construction. Theoretically, the miner will not have to be exposed to an un-reinforced mine ceiling ever again.

The flexible bolting arm folds down on the vehicle reducing the size by half compared to existing bolting machines, improving both flexibility in transport and reducing risks of collision while tramming to the site.

Corporate Sponsors: Atlas Copco and Boliden AB

Designer: Dawid Dawod